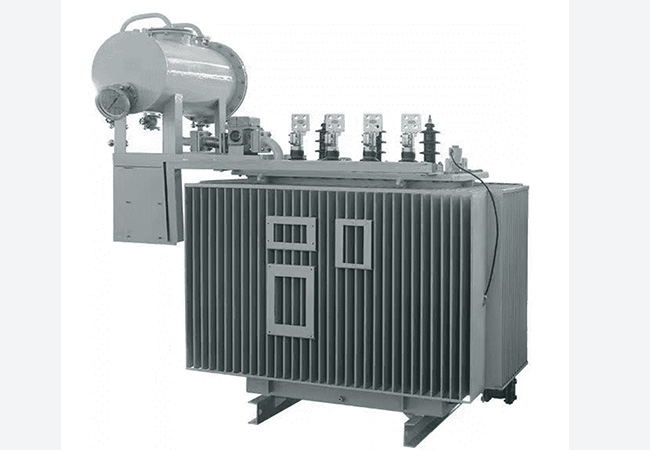

35KV oil-immersed distribution transformer

07-03 2025 | By:

35KV oil-immersed distribution transformer

Product model: S11/S13/S18/S20/S22

Rated capacity: 50KVA to 3150KVA

Rated voltage: 30KV, 33KV, 35KV, 38.5KV

I. Scope of application

Transformers with rated capacity ranging from 50KVA to 3150KVA are suitable for power systems with AC 50Hz/60Hz and working voltage of 35KV and below, as substation equipment in the fields of power transmission and distribution, infrastructure, public transportation, construction and housing, industry, information technology and new energy.

2. Product standards

GB/T1094.1-5 GB/T1094.7 JB/T10088 GB/T6451

GB/T7595 JB/T3837 GB20052 IEC60076

3. Conditions of use

3.1 Altitude: ≤1000M;

3.2 Ambient temperature: -40℃~+40℃;

3.3 Outdoor wind speed: ≤45m/s

3.4 Ground inclination: ≤3°

3.5 Earthquake resistance: horizontal acceleration ≤0.3m/s2, vertical acceleration ≤0.15m/s2

3.6 Installation location: no fire, explosion hazard, severe dirt, chemical corrosion and severe vibration;

3.7 If the above conditions of use cannot meet the requirements, the user can negotiate with the company to resolve the problem.

4. Product Advantages

Core: The 45° full-slant step joint process is adopted to effectively reduce no-load loss, no-load current and core noise.

The clamp and pull plate structure are used to make the core as a whole stable and firm, thereby improving the ability to resist short circuits and impacts.

Coil: The high voltage adopts a cylindrical type, and the low voltage adopts a cylindrical type or foil type, which improves the ability to resist short circuits.

An oil guide structure is provided inside the winding to improve the oil flow path, thereby reducing temperature rise and improving load capacity.

Oil tank: It is a fully sealed bell-shaped structure, and the oil tank reinforcement iron adopts a corrugated folding plate structure, with fewer welds and high mechanical strength.

The cooling device adopts a plate radiator, which has a faster circulation speed, high heat dissipation efficiency, and improved overload capacity.

Body: All insulating parts and the welding parts of the winding head and lead wire are rounded.

The upper and lower parts of the body are positioned with rigidity to ensure that the body does not shift under various transportation conditions.

You may also find these interesting: