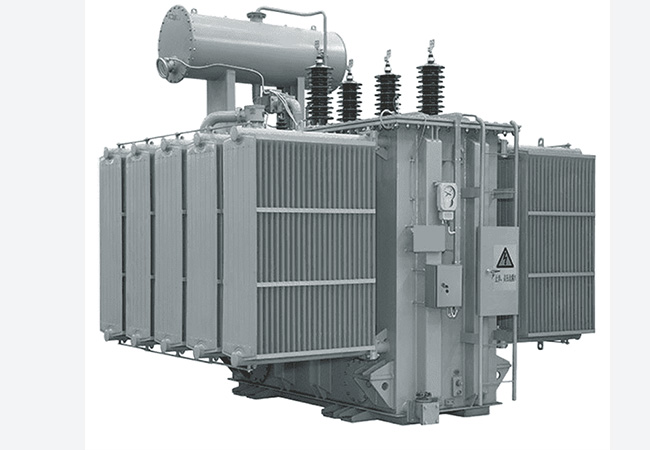

35KV oil-immersed power transformer

07-03 2025 | By:

35KV oil-immersed power transformer

Product model: S11/S13/S18/S20/S22

Rated capacity: 630KVA to 31500KVA

Rated voltage: 30KV, 33KV, 35KV, 38.5KV

I. Scope of application

Oil-immersed power transformers with rated capacity ranging from 630KVA to 31500KVA are suitable for power systems with AC 50Hz/60Hz and working voltage of 35KV and below, as substation equipment for small and medium-sized substations.

2. Product standards

GB/T1094.1-5 GB/T1094.7 JB/T10088 GB/T6451

GB/T7595 JB/T3837 GB20052 IEC60076

3. Conditions of use

3.1 Altitude: ≤1000M;

3.2 Ambient temperature: -40℃~+40℃;

3.3 Outdoor wind speed: ≤45m/s

3.4 Ground inclination: ≤3°

3.5 Earthquake resistance: horizontal acceleration ≤0.3m/s2, vertical acceleration ≤0.15m/s2

3.6 Installation location: no fire, explosion hazard, severe dirt, chemical corrosion and severe vibration;

3.7 If the above conditions of use cannot meet the requirements, the user can negotiate with the company to resolve the problem.

4. Product Advantages

Core: 45° full-slant step joint process is adopted, which effectively reduces no-load loss, no-load current and core noise;

The clamp and pull plate structure are used to make the core as a whole stable and firm, thereby improving the ability to resist short circuit and impact.

Coil: High voltage adopts cylindrical type, low voltage adopts cylindrical type or foil type, which improves the ability to resist short circuit;

An oil guide structure is provided inside the winding to improve the oil flow path, thereby reducing temperature rise and improving load capacity.

Oil tank: It is a fully sealed bell-shaped structure, and the oil tank reinforcement iron adopts corrugated folding plate structure, with fewer welds and high mechanical strength;

The cooling device adopts a plate radiator, which has faster circulation speed, high heat dissipation efficiency, and improved overload capacity.

Body: All insulating parts and the welding parts of the winding head and lead wire are rounded;

The upper and lower parts of the body are positioned with rigidity to ensure that the body does not shift under various transportation conditions.

Safety: The transformer is equipped with protective devices such as gas relay, pressure relief valve, oil level gauge, thermometer and desiccant.

You may also find these interesting: