Dry-Type Transformer Parts and Common Loss Causes

10-10 2025 | By:

Dry-Type Transformer Parts and Common Loss Causes

Keywords: dry-type transformer, transformer parts, transformer losses, insulation materials, FR4 epoxy board, ZTelec manufacturer, power transformer efficiency

Introduction

Dry-type transformers are widely used in commercial buildings, industrial plants, and power distribution systems because of their safety, environmental protection, and low maintenance. Unlike oil-immersed transformers, they rely on air cooling and solid insulation to dissipate heat and ensure reliable performance.

Over time, certain transformer parts wear out or degrade, leading to efficiency loss or electrical faults. Understanding these common consumable parts and loss causes helps reduce downtime and improve service life.

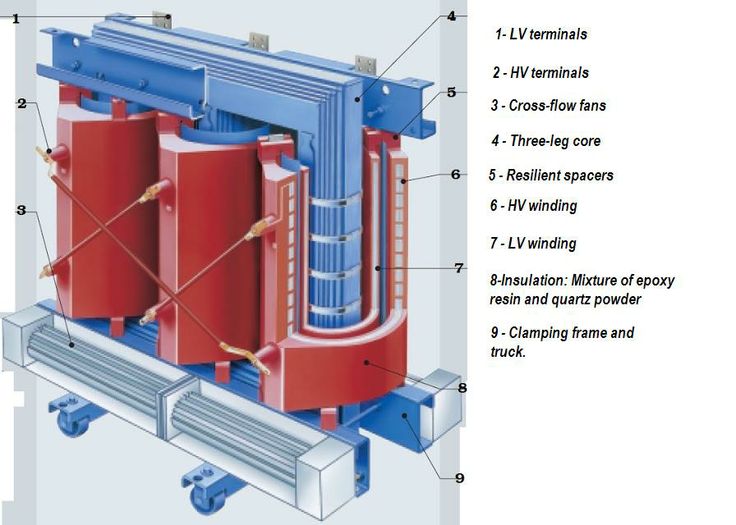

Main Parts of a Dry-Type Transformer

1. Core

The core is made of laminated silicon steel sheets and serves as the magnetic circuit of the transformer. It minimizes hysteresis and eddy current losses.

- Common issue: Iron loss due to magnetic flux leakage or material degradation.

- Maintenance tip: Ensure proper lamination and tight clamping to reduce vibration and noise.

2. Windings (Coils)

The windings are made of copper or aluminum conductors insulated with epoxy resin or NOMEX paper. They transfer electrical energy between voltage levels.

- Wear parts: Conductors, insulation layers, and coil end fittings.

- Causes of loss: Overheating, short circuits, and partial discharge.

3. Insulation Materials

In dry-type transformers, insulation materials such as FR4 epoxy board, DMD paper, NOMEX aramid paper, and glass fiber tubes play key roles. They separate conductive parts and withstand high voltage stress.

- Typical issues: Thermal aging, moisture absorption, and mechanical stress.

- Prevention: Use certified insulation parts from ZTelec for better performance.

4. Cooling System

Dry-type transformers use air natural (AN) or air forced (AF) cooling. Fans and ventilation paths remove heat from the windings and core.

- Common failures: Fan wear, dust accumulation, poor ventilation.

- Impact: Overheating accelerates insulation aging and increases load loss.

5. Terminal Connectors and Bus Bars

These connect the transformer to external circuits and often experience wear.

- Consumable parts: Bolts, connectors, insulating supports.

- Failure causes: Corrosion, loose joints, poor contact causing local heating.

6. Enclosure and Support Structure

The enclosure protects internal components from dust and mechanical damage. Using FR4 or GPO-3 insulation supports improves stability and safety.

Common Losses in Dry-Type Transformers

1. No-Load Loss (Core Loss)

Occurs in the magnetic core when the transformer is energized but not loaded.

- Causes: Hysteresis and eddy current losses.

- Solutions: Use high-quality silicon steel and proper lamination.

2. Load Loss (Copper Loss)

Occurs when current flows through the windings.

- Causes: Conductor resistance (I²R loss), poor connections, and eddy currents.

- Solutions: Tighten terminals regularly, improve cooling, and use high-purity copper.

Other Causes of Transformer Efficiency Loss

| Category | Typical Reason | Preventive Measures |

|---|---|---|

| Insulation Aging | Heat, moisture, and vibration degrade insulation | Use epoxy resin cast coils and NOMEX insulation |

| Dust & Contamination | Blocks airflow and causes partial discharge | Clean ventilation channels regularly |

| Overloading | Excess current increases heat and winding stress | Maintain load within rated capacity |

| Vibration & Noise | Core loosening or unbalanced winding | Use anti-vibration mounts and inspect clamping |

How to Reduce Transformer Loss and Extend Service Life

- Use High-Quality Insulation Materials: FR4 epoxy boards, NOMEX paper, and DMD composites from ZTelec ensure long-term reliability.

- Improve Cooling Efficiency: Maintain airflow and clean fan systems.

- Perform Regular Maintenance: Tighten terminals, test insulation, and monitor temperature rise.

- Monitor Operating Conditions: Track load level, humidity, and temperature.

- Work with Reliable Manufacturers: Partner with ZTelec for certified transformer parts and accessories.

You may also find these interesting: