Epoxy resin cracks in dry-type transformers: analysis and measures

06-12 2025 | By:

Epoxy resin cracks in dry-type transformers: analysis and measures

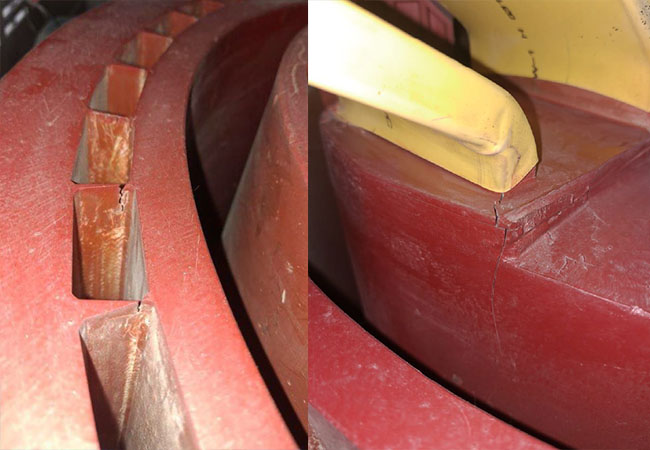

Checking whether there is cracking on the epoxy resin on the coil surface is a very important item in the cleaning and maintenance of dry-type transformers. Discharge on the coil surface or excessive local discharge can cause insulation damage to the transformer if it is operated with a problem for a long time.

Note: If the epoxy resin on the coil surface cracks, even if there is no abnormality in the preventive test, it can only continue to operate under the condition of clean operating environment and low humidity. If the operating environment is not satisfied, it should be handled immediately.

According to experience and data statistics, most of the cracked parts appear on the boss, silicon steel sheet and about two-thirds of the height of the middle and upper part of the coil. During the cleaning and maintenance process, the above parts should be checked in particular.

1. Cause analysis

The cracking of epoxy resin on the coil surface is caused by local internal stress, and the local internal stress is mainly caused by the following two points:

1. Due to excessive temperature unevenness, the center and the edge have different degrees of thermal expansion, resulting in internal stress.

2. The thermal expansion coefficient of resin is much larger than that of copper and glass fiber. The thermal expansion degree of various materials is different, which leads to the generation of internal stress.

From the above analysis, it can be seen that the cracking of epoxy resin on the surface of the coil is mainly related to temperature. There are many reasons for the temperature change of the transformer, which will be introduced in the next article.

2. Temporary measures

1. Wipe with a brush and alcohol to check and find out the specific location and range of the crack.

2. Use a hacksaw blade to expand the crack to 2 mm.

3. Sand the rough part of the crack with sandpaper, and then wipe it clean with alcohol.

4. Squeeze silicone rubber into the crack and then use a saw blade to spread it evenly.

5. After standing for half an hour, treat it again. Finally, the crack needs to be completely filled with silicone rubber and spread evenly.

Note: It is difficult to make a broken mirror round. This is a temporary disposal measure. After the disposal is completed, for safety reasons, you need to contact the manufacturer immediately to replace the transformer. After the preventive test is passed, the transformer that has been temporarily disposed can continue to operate to meet the production cycle required by the supplier.

You may also find these interesting: