35kV S11, SZ11 oil-immersed power transformer

06-18 2025 | By:

Product Introduction

The 35kV S11 and SZ11 series products produced by our company comply with the International Electrotechnical Commission IEC60076 and the National Standard of the People’s Republic of China GB1094 “Power Transformer” and GB/T6451 “Technical Parameters and Requirements for Three-Phase Oil-Immersed Power Transformers“. The voltage can be adjusted manually, electrically or automatically within the voltage regulation range on the primary side with the help of the on-load voltage regulator to ensure the stability of the output voltage. The 35kV transformer above 16000kVA adopts the bell type, which greatly enhances the mechanical strength of the oil tank and improves the appearance quality of the transformer. This product is an upgraded product with good operating economic benefits.

Product Features

1. Low loss and significant energy saving. In particular, the no-load loss is greatly reduced, which is about 25% lower than the national standard GB/T6451-2008 on average.

2. The core is made of high-quality cold-rolled silicon steel sheets, and the domestic advanced cross-cutting line has shear burrs less than 0.02mm, full oblique joints, no punching, and no stacking of iron yokes; the core columns are stacked with double H adhesive to make the three columns and two yokes of the core a tight, flat, and compact whole, which effectively reduces the no-load loss, no-load current, and noise of the transformer.

3. The transformer coil uses high-purity oxygen-free copper, which effectively reduces the copper loss. The coil pads and support bars are rounded, the electric field is uniform, and the reliability is increased. The inner winding support is strengthened to improve its stability and prevent instability and deformation. For products with a capacity of more than 16000KVA, the inner and outer coils use a unified integral support plate and pressure plate to assemble the coils and press them back at the same time, ensuring the consistency of the height size of each coil in the axial direction, and improving the transformer’s ability to resist sudden short circuits.

4. The plate clamps and side beams form a solid frame structure, and the body and the oil tank are rigidly positioned on six sides, so that the body can withstand the impact test under various transportation conditions without displacement. If the impact during product transportation is less than the specified value, the site can be directly tested and put into operation without a hanging inspection, which reduces a lot of work on the product site.

5. The oil tank wall is made of integral steel plate, which is folded into a corrugated structure by a large press, reducing welds, increasing mechanical strength, expanding the heat area, and improving heat dissipation. At the same time, the corrugated box wall avoids plane reflection of sound waves and plays a role in reducing noise. The overall transformer is beautiful and simple.

6. The capsule oil storage cabinet is used to effectively slow down the aging of transformer oil; the pointer oil level gauge can avoid the occurrence of false oil level and solve the problem of transformer oil aging under light; the gas relay with a gas collection device is easy to maintain and operate.

7. For the original traditional sealing structure, especially the places where oil leakage is prone to occur, starting from material procurement control, ensure that the steel is not rusted, bumped, scratched, or hammered, and the sealing part of the oil tank is specially processed, and the box body is sprayed with paint as a whole to remove the sharp corners, burrs, and welding slag generated during processing in the box body, and strengthen the adhesion of the paint.

Normal use conditions

High temperature +40℃

Average temperature of hot month +30℃

Average temperature of hot year +20℃

Low temperature -25℃

Altitude does not exceed 1000m

No obvious pollution in the installation environment

Outdoor installation

35kV S11 type non-excitation voltage regulating power transformer Technical data sheet

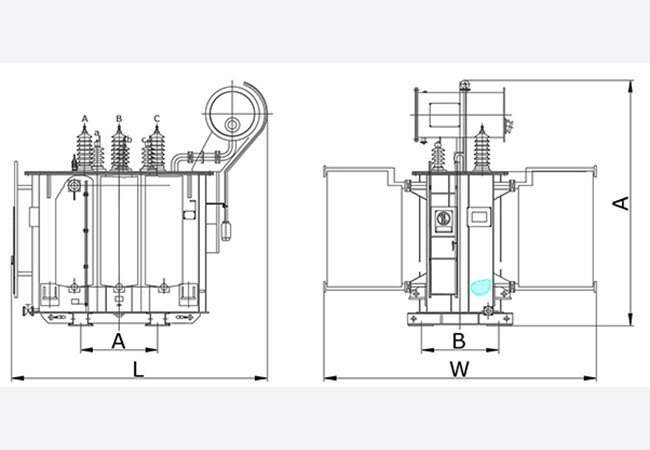

| Type | Voltage combination(kV) | Link group label | loss (kW) | No-load current (%) | Short circuit impedance(%) | weight(kg) | Dimensions(mm) | gauge(mm) | ||||||

| HV | Tap range | LV | No load | load | Oil weight | Total weight | L | W | H | A×B | ||||

| S11-800/35 | 33

35 38.5 |

±5%

OR ±2×2.5% |

3.15 3.3

6.3 10.5 11 15 |

Yd11 | 0.98 | 9.41 | 1 | 6.5 | 970 | 3260 | 2340 | 1475 | 2340 | 820×820 |

| S11-1000/35 | 1.15 | 11.54 | 1 | 1090 | 3970 | 2480 | 1640 | 2430 | 820×850 | |||||

| S11-1250/35 | 1.41 | 13.94 | 0.9 | 1240 | 4850 | 2500 | 1650 | 2580 | 1070×1070 | |||||

| S11-1600/35 | 1.7 | 16.67 | 0.8 | 1320 | 5200 | 2540 | 1690 | 2600 | ||||||

| S11-2000/35 | 2.18 | 18.38 | 0.7 | 1515 | 5990 | 2580 | 1790 | 2630 | ||||||

| S11-2500/35 | 2.56 | 19.67 | 0.6 | 1620 | 6720 | 2650 | 1800 | 2690 | ||||||

| S11-3150/35 | 3.04 | 23.09 | 0.56 | 7 | 2150 | 8750 | 2800 | 2890 | 2730 | 1070×1275 | ||||

| S11-4000/35 | 3.62 | 27.36 | 0.56 | 2235 | 9630 | 2870 | 2990 | 2780 | ||||||

| S11-5000/35 | 4.32 | 31.38 | 0.48 | 2900 | 11500 | 3170 | 3500 | 3000 | ||||||

| S11-6300/35 | 5.25 | 35.06 | 0.48 | 7.5 | 3800 | 13900 | 3200 | 3550 | 3200 | |||||

| S11-8000/35 | YNd11 | 7.2 | 38.48 | 0.42 | 4150 | 17900 | 3560 | 3660 | 3380 | |||||

| S11-10000/35 | 8.7 | 45.32 | 0.42 | 4600 | 18800 | 3650 | 3700 | 3450 | 1475×1475 | |||||

| S11-12500/35 | 10.08 | 53.87 | 0.4 | 8 | 5300 | 24000 | 3770 | 3870 | 3750 | |||||

| S11-16000/35 | 12.16 | 65.84 | 0.4 | 6800 | 29000 | 4500 | 4000 | 4150 | ||||||

| S11-20000/35 | 14.4 | 79.52 | 0.4 | 8000 | 33000 | 4650 | 4100 | 4300 | ||||||

| S11-25000/35 | 17.02 | 94.05 | 0.32 | 9650 | 37000 | 4950 | 4250 | 4330 | ||||||

| S11-31500/35 | 20.22 | 112.8 | 0.32 | 10800 | 42000 | 5200 | 4400 | 4450 | 2040×1475 | |||||

2、35kV SZ11 on-load voltage regulating transformer technical data sheet

| TYPE | Voltage combination(kV) | Link group label | loss (kW) | No-load current (%) | Short circuit impedance(%) | weight(kg) | Dimensions(mm) | gauge(mm) | |||||||

| HV | Tap range | LV | No load | load | Oil weight | Total weight | L | W | H | A×B | |||||

| SZ11-2000/35 | 35

38.5 |

±3×2.5% | 6.3 10.5 11 15 | Yd11 | 2.3 | 19.24 | 0.8 | 6.5 | 1790 | 6570 | 3090 | 2190 | 2450 | 1070×1070 | |

| SZ11-2500/35 | 2.72 | 20.64 | 0.8 | 2120 | 7560 | 3100 | 2300 | 2540 | |||||||

| SZ11-3150/35 | 3.23 | 24.71 | 0.72 | 2470 | 9130 | 3200 | 2950 | 2540 | 1070×1275 | ||||||

| SZ11-4000/35 | 3.87 | 29.16 | 0.72 | 7 | 2960 | 11000 | 3600 | 2970 | 2870 | ||||||

| SZ11-5000/35 | 4.64 | 34.2 | 0.68 | 3160 | 12130 | 3640 | 3320 | 2900 | |||||||

| SZ11-6300/35 | 5.63 | 36.77 | 0.68 | 3490 | 14370 | 3920 | 3500 | 2970 | |||||||

| SZ11-8000/35 | YNd11 | 7.87 | 40.61 | 0.6 | 7.5 | 4700 | 18300 | 4380 | 3750 | 3300 | 1475×1475 | ||||

| SZ11-10000/35 | 9.28 | 48.05 | 0.6 | 5400 | 20900 | 4430 | 3800 | 3350 | |||||||

| SZ11-12500/35 | 10.94 | 56.86 | 0.56 | 6000 | 29600 | 4560 | 3850 | 3500 | |||||||

| SZ11-16000/35 | 13.17 | 70.32 | 0.54 | 8 | 8100 | 24400 | 4780 | 4050 | 4160 | ||||||

| SZ11-20000/35 | 15.57 | 82.78 | 0.54 | 8800 | 34000 | 4960 | 4200 | 4270 | |||||||

You may also find these interesting: