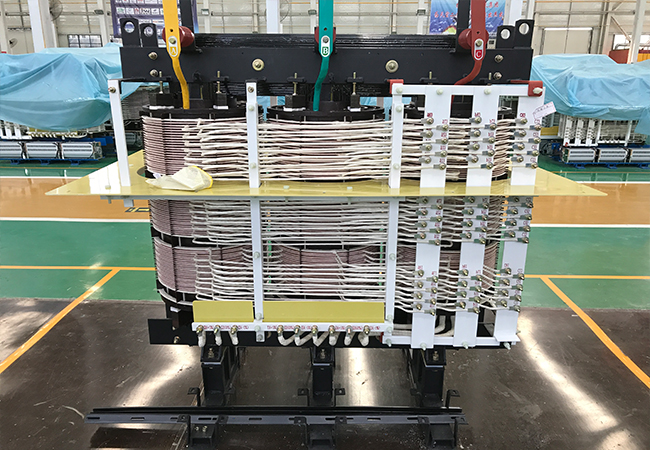

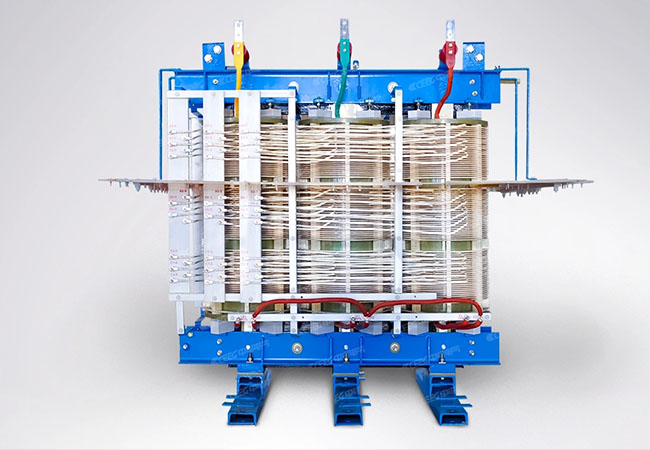

ZTSFG (H) dry-type multi-winding phase-shifting rectifier transformer

09-08 2025 | By:

ZTSFG (H) dry-type multi-winding phase-shifting rectifier transformer

Dry-type phase-shifting rectifier transformers are designed specifically for multi-pulse rectification systems. They achieve harmonic suppression through phase-shifting windings and are widely used in industrial applications requiring high-precision DC power supplies, such as high-power rectifiers, high-voltage inverters, and bidirectional charging and discharging applications for energy storage and charging pile PCS modules. They operate by shifting the secondary winding of the transformer to achieve phase shifting. Specifically, this is achieved by adjusting the secondary winding connection, such as adopting the complex Yanbian delta connection, which lies between delta and star connections.

Harmonic Suppression: 6/12/18/24/36/48-pulse configurations reduce grid harmonics (THDi) to ≤3% (compliant with IEC 61000-3-6).

Voltage Adaptation: Input voltages cover 0.4kV to 35kV, and outputs match rectifier equipment requirements (e.g., DC 600V to 1500V).

Dynamic Voltage Regulation: Output voltage deviation ≤±2% during load fluctuations.

Electrical Isolation: Secondary-side insulation withstand voltage of 3.5kV AC/1min, leakage current <10mA.

Application features: It uses air or gas cooling, has multiple independent windings, and can achieve multi-voltage output or electrical isolation through electromagnetic coupling of different windings to meet complex load requirements.

ZTSFG (H) dry-type multi-winding phase-shifting rectifier transformer

II. Environmental Requirements

Temperature: Operating environment: -25°C to +40°C (maximum temperature rise ≤ 80K, Class H insulation)

Humidity: Relative humidity ≤ 95% (non-condensing), Altitude ≤ 4000m (altitude correction factor required)

Electrical requirements: Grid voltage fluctuation ±10%, frequency deviation ±2%, short-circuit capacity ≥ 25kA

Mechanical requirements: Vibration resistance ≤ 0.5g (10-500Hz), installation tilt ≤ 3°

Protection level: Available in IP00, IP23 (natural cooling), or IP54 (forced air cooling)

ZTSFG (H) dry-type multi-winding phase-shifting rectifier transformer

Phase Shift Accuracy: Phase difference 15° ± 0.5° (6, 12, 18, 24, 36, 48 pulse systems with different requirements)

Efficiency: Full-load efficiency ≥ 98.5% (GB 20052 Level 1 energy efficiency rating)

Insulation Class: H (180°C temperature resistance, optional F)

Cooling Method: AN/AF (natural/forced air cooling), temperature-controlled fan auto-start/stop

Structural Design: Epoxy resin vacuum casting or open-type

Intelligent Interface: Optional RS485/Modbus TCP, supporting online temperature and harmonics monitoring

ZTSFG (H) dry-type multi-winding phase-shifting rectifier transformer

1. High Efficiency and Energy Saving: Low-loss design (no-load loss is 15% lower than the national standard), saving ≥10% in annual operating costs;

2. Compact Structure: 40% smaller than traditional oil-immersed units, supports wall mounting (minimum spacing 300mm);

3. High Reliability: Fully enclosed structure (IP54), passes a 72-hour salt spray test, and has a service life of ≥25 years;

4. Flexible Configuration: Supports multi-winding output (up to four phase-shifted groups), with a capacity range of 100kVA to 20MVA;

5. Low Inrush Current: Through optimized coil and core design and precise calculation of the core’s magnetic saturation value, the impact and effects of inrush current are minimized.

| Type | Ratedcapacity(kVA) | Qtyof secwindings | Shortcircuit impedance(%) | Dimension (L×WxH,mm) | Totalweight(kg) |

| ZT(P)SFG(H)-250/6 | 250 | 9 12 15 18 21 | 6-9% | 1300×880×1440 | 970 |

| ZT(P)SFG(H)-315/6 | 315 | 1300×880×1440 | 1110 | ||

| ZT(P)SFG(H)-400/6 | 400 | 1360×880×1450 | 1200 | ||

| ZT(P)SFG(H)-500/6 | 500 | 1360×960×1490 | 1380 | ||

| ZT(P)SFG(H)-630/6 | 630 | 1360×960×1500 | 1530 | ||

| ZT(P)SFG(H)-710/6 | 710 | 1440×960×1500 | 1680 | ||

| ZT(P)SFG(H)-800/6 | 800 | 1480×960×1520 | 1790 | ||

| ZT(P)SFG(H)-900/6 | 900 | 1480×960×1540 | 1940 | ||

| ZT(P)SFG(H)-1000/6 | 1000 | 1500×960×1550 | 2110 | ||

| ZT(P)SFG(H)-1120/6 | 1120 | 1550×960×1580 | 2190 | ||

| ZT(P)SFG(H)-1250/6 | 1250 | 1580×960×1630 | 2440 | ||

| ZT(P)SFG(H)-1400/6 | 1400 | 1610×1020×1630 | 2610 | ||

| ZT(P)SFG(H)-1600/6 | 1600 | 1660×1020×1680 | 2890 | ||

| ZT(P)SFG(H)-1800/6 | 1800 | 1650×1020×1740 | 3060 | ||

| ZT(P)SFG(H)-2000/6 | 2000 | 1680×1020×1800 | 3420 | ||

| ZT(P)SFG(H)-2250/6 | 2250 | 1720×1020×1840 | 3810 | ||

| ZT(P)SFG(H)-2500/6 | 2500 | 1760×1020×1860 | 4120 | ||

| ZT(P)SFG(H)-2800/6 | 2800 | 1800×1020×1860 | 4490 | ||

| ZT(P)SFG(H)-3000/6 | 3000 | 1820×1120×1860 | 4840 | ||

| ZT(P)SFG(H)-3150/6 | 3150 | 1860×1120×1900 | 5200 | ||

| ZT(P)SFG(H)-3500/6 | 3500 | 1900×1120×1940 | 5620 | ||

| ZT(P)SFG(H)-3750/6 | 3750 | 1960×1120×2050 | 5810 | ||

| ZT(P)SFG(H)-4000/6 | 4000 | 1990×1200×2050 | 6210 | ||

| ZT(P)SFG(H)-4500/6 | 4500 | 2070×1200×2100 | 6910 | ||

| ZT(P)SFG(H)-5000/6 | 5000 | 2150×1200×2100 | 7440 | ||

| ZT(P)SFG(H)-6300/6 | 6300 | 2200×1300×2140 | 8860 | ||

| ZT(P)SFG(H)-8000/6 | 8000 | 2200×1300×2200 | 9670 |

| Type | Ratedcapacity(kVA) | Qtyof secwindings | Shortcircuit impedance(% ) | Dimension(LxWxH,mm ) | Total weight(kg) |

| ZT(P)SFG(H)-315/10 | 315 | 15 18 21 24 27 30 36 | 6-9% | 1380×920×1450 | 1090 |

| ZT(P)SFG(H)-400/10 | 400 | 1380×920×1490 | 1250 | ||

| ZT(P)SFG(H)-500/10 | 500 | 1420×960×1520 | 1410 | ||

| ZT(P)SFG(H)-630/10 | 630 | 1450×960×1550 | 1640 | ||

| ZT(P)SFG(H)-710/10 | 710 | 1480×960×1580 | 1780 | ||

| ZT(P)SFG(H)-800/10 | 800 | 1530×960×1620 | 1860 | ||

| ZT(P)SFG(H)-900/10 | 900 | 1580×960×1640 | 2050 | ||

| ZT(P)SFG(H)-1000/10 | 1000 | 1640×960×1660 | 2250 | ||

| ZT(P)SFG(H)-1120/10 | 1120 | 1640×1020×1680 | 2300 | ||

| ZT(P)SFG(H)-1250/10 | 1250 | 1680×1020×1720 | 2470 | ||

| ZT(P)SFG(H)-1400/10 | 1400 | 1700×1020×1760 | 2810 | ||

| ZT(P)SFG(H)-1600/10 | 1600 | 1780x1020x1800 | 3040 | ||

| ZT(P)SFG(H)-1800/10 | 1800 | 1780×1020×1820 | 3360 | ||

| ZT(P)SFG(H)-2000/10 | 2000 | 1780×1020×1860 | 3690 | ||

| ZT(P)SFG(H)-2250/10 | 2250 | 1780×1020×1900 | 4170 | ||

| ZT(P)SFG(H)-2500/10 | 2500 | 1800×1020×1900 | 4410 | ||

| ZT(P)SFG(H)-2800/10 | 2800 | 1840×1120×1950 | 4720 | ||

| ZT(P)SFG(H)-3000/10 | 3000 | 1880×1120×1950 | 5020 | ||

| ZT(P)SFG(H)-3150/10 | 3150 | 1920×1120×2000 | 5400 | ||

| ZT(P)SFG(H)-3500/10 | 3500 | 1980×1120×2050 | 5400 | ||

| ZT(P)SFG(H)-3750/10 | 3750 | 2010×1200×2050 | 5900 | ||

| ZT(P)SFG(H)-4000/10 | 4000 | 2060×1200×2080 | 6360 | ||

| ZT(P)SFG(H)-4500/10 | 4500 | 2120×1200×2100 | 6960 | ||

| ZT(P)SFG(H)-5000/10 | 5000 | 2200×1200×2150 | 7440 | ||

| ZT(P)SFG(H)-6300/10 | 6300 | 2250×1300×2150 | 8950 | ||

| ZT(P)SFG(H)-8000/10 | 8000 | 2250×1350×2250 | 10900 |

You may also find these interesting: