Containerised Substations (CSS) | Compact & Container Type Transformers

01-13 2026 | By:

With the rapid growth of urban infrastructure, renewable energy, and industrial power networks, containerised substations (CSS) have become a core solution for reliable and fast-deployable power distribution. Also known as compact substations, container type transformers, or prefabricated container substations, these modular units combine safety, efficiency, and mobility for modern electrical systems.

+86 166 5027 3776 Immediately communicate with engineers for a quote!

What Is a Containerised Substation (CSS)?

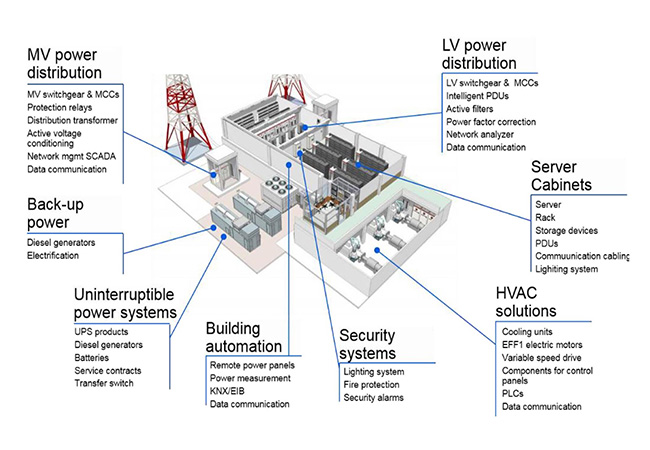

A containerised substation is a factory-assembled, fully integrated power distribution unit installed inside a transportable container. It typically includes:

-

High voltage (HV) switchgear

-

Power transformer

-

Low voltage (LV) switchgear

-

Protection, control, and monitoring systems

-

Auxiliary equipment for operational safety

The complete unit allows plug-and-play installation, reducing civil works, installation time, and operational risks.

Common Names of Containerised Substations

These substations are referred to differently across regions and industries:

-

Containerised Substation (CSS)

-

Container Type Transformer

-

Compact Substation

-

Prefabricated Substation

-

Skid Mounted Substation

-

Modular Substation

-

Package Substation

-

Mobile Substation

All these names highlight the modular, portable, and integrated design, ideal for fast deployment in any location.

Typical Specifications

class=”w-fit min-w-(–thread-content-width)” data-start=”1857″ data-end=”2334″>

| Parameter | Typical Range |

|---|---|

| Rated Voltage | 6kV / 10kV / 11kV / 20kV / 33kV / 35kV |

| Transformer Capacity | 100 kVA – 5000 kVA |

| Frequency | 50Hz / 60Hz |

| Cooling Method | ONAN / ONAF |

| HV Switchgear | SF6 RMU / Vacuum RMU |

| LV Switchgear | GGD / MNS / Custom Panels |

| Protection Degree | IP33 – IP54 |

| Container Size | 20ft / 40ft / Custom Sizes |

| Installation | Outdoor / Indoor / Semi-Outdoor |

| Service Life | ≥ 25 Years |

+86 166 5027 3776 Immediately communicate with engineers for a quote!

Certification & Compliance

High-quality containerised substations meet strict international and national standards:

-

IEC 62271 – High Voltage Switchgear

-

IEC 60076 – Transformers

-

IEC 61439 – Low Voltage Switchgear

-

IEEE / ANSI Standards

-

GB Standards (China)

-

ISO 9001 – Quality Management

-

ISO 14001 – Environmental Management

-

CE Certification

-

SGS / TUV Third-Party Testing

Each unit undergoes routine, type, and factory acceptance tests before delivery to ensure safety and reliability.

+86 166 5027 3776 Immediately communicate with engineers for a quote!

Key Advantages of Containerised Substations

-

Factory-assembled, ready-to-install

-

Compact footprint and modular design

-

High mobility for remote or temporary sites

-

Excellent safety and environmental protection

-

Reduced installation time and cost

-

Easy maintenance and long service life

-

Smart monitoring and digital integration

Application Scenarios

Containerised substations are widely used in:

-

Urban power distribution and city substations

-

Renewable energy projects (solar, wind)

-

Mining, oil, and gas facilities

-

Industrial parks and factories

-

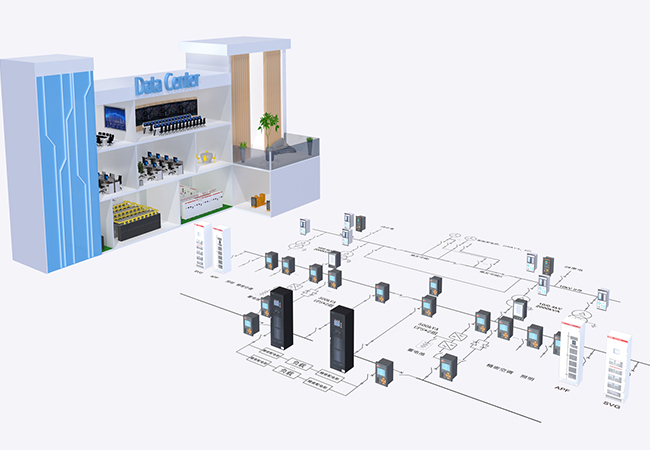

Data centers and commercial complexes

-

Airports, railways, and ports

-

Temporary construction power supply

-

Remote or harsh environmental locations

How to Choose a Containerised Substation

When selecting a CSS or container type transformer, consider:

-

Voltage level and transformer capacity requirements

-

Environmental conditions (outdoor/indoor, temperature, humidity)

-

Cooling and ventilation method

-

Protection and fire safety requirements

-

International or local certifications

-

Manufacturer experience and project references

A professional supplier can provide customized solutions to match the exact project requirements.

Future Trends

The containerised substation market is evolving toward:

-

Smart digital monitoring and IoT integration

-

Higher energy efficiency and low-loss transformers

-

Modular expansion and plug-and-play designs

-

Environmentally friendly materials

-

Rapid deployment and temporary site flexibility

These trends make CSS solutions ideal for modern, renewable, and flexible power networks.

+86 166 5027 3776 Immediately communicate with engineers for a quote!

You may also find these interesting: