ZTelec Yuguang Furnace Transformers: Complete Classification for Industrial Heating Systems

12-04 2025 | By:

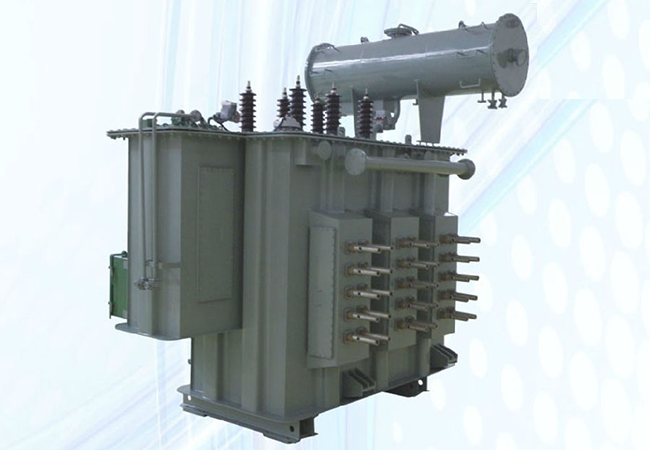

Industrial furnace transformers are specialized power transformers used to supply heating furnaces across metallurgy, heat treatment, and industrial manufacturing. ZTelec Yuguang Transformer Factory, as a professional transformer manufacturer with over 20 years of experience, provides a full range of oil-immersed furnace transformers from 100 kVA to 80 MVA, supporting customized voltage regulation, cooling methods, and furnace-specific designs.

What Is an Industrial Furnace Transformer?

An industrial furnace transformer delivers controlled, adjustable voltage to heating equipment with unique load characteristics—such as low resistance, ultra-high current, or sharply changing impedance. Yuguang furnace transformers are engineered for high short-circuit strength, low loss, and stable long-term operation, making them suitable for global steel plants, foundries, and heat-treatment workshops.

1. Resistance Furnace Transformer (By ZTelec Yuguang)

Used in:

-

Mechanical parts heating

-

Heat treatment

-

Powder metallurgy sintering

-

Non-ferrous metal melting

-

Salt-bath furnaces

Resistance furnaces often have low or significantly varying heating-element resistance. Therefore, Yuguang resistance furnace transformers provide stable step-down voltage and precise adjustment to match the heating curve.

Cooling Types

-

Small capacity: dry-type, natural air cooling

-

Medium capacity: oil-immersed, ONAN cooling

-

Large capacity: forced oil circulation + water cooling

2. Arc Furnace Transformer (Steel-Making Furnace Transformer)

ZTelec Yuguang arc furnace transformers are widely used in electric arc steel-making equipment.

Key Features

-

High capacity: 5 MVA – 80 MVA

-

Wide secondary voltage adjustment

-

High output current: 5,000–40,000 A

-

Withstands 20% overload for 2 hours

-

Designed with high leakage impedance to limit short-circuit current

Voltage Regulation Options

-

On-load tap changer (OLTC) for continuous voltage control

-

Off-load tap changer for medium and small furnaces

3. Induction Furnace Transformer

Induction furnaces melt ferrous and non-ferrous metals using electromagnetic induction. Yuguang induction furnace transformers provide optimized coupling for high-frequency or power-frequency melting systems.

Types

-

Core-type induction furnace

-

Coreless induction furnace

A core-type design uses a single-turn secondary winding, enabling extremely high induced current for efficient melting.

4. Structural Advantages of ZTelec Yuguang Furnace Transformers

▪ Premium Magnetic Core

-

Grain-oriented silicon steel

-

Automatic step-lap cutting

-

45° full miter joints

-

No punching or strap binding

▪ Advanced Coil & Insulation System

-

Excellent axial/radial mechanical strength

-

High short-circuit withstand capability

-

Overload-friendly thermal design

-

Low loss per IEC/GB standards

▪ Flexible Voltage Regulation Designs

-

OLTC for large furnaces (no series reactor)

-

Off-load tap changer for medium-small units

-

Optional series reactor to modify furnace impedance

Industrial Furnace Transformer Specifications

| Parameter | Resistance Furnace Transformer | Arc Furnace Transformer | Induction Furnace Transformer |

|---|---|---|---|

| Brand / Manufacturer | ZTelec Yuguang Transformer Factory | ZTelec Yuguang Transformer Factory | ZTelec Yuguang Transformer Factory |

| Rated Capacity | 100 kVA – 8 MVA | 5 MVA – 80 MVA | 500 kVA – 30 MVA |

| Primary Voltage (HV) | 6 / 10 / 11 / 33 kV | 6 / 10 / 11 / 33 kV | 6 / 10 / 11 / 33 kV |

| Secondary Voltage (LV) | 20–1200 V adjustable | 60–800 V wide-range adjustable | Single-turn ultra-low voltage |

| Output Current | High current, low voltage | 5,000–40,000 A | Extremely high induced current |

| Cooling Method | Dry-type / ONAN / OFWF | ONAN / ONAF / OFWF | OFWF (water-cooled coil) |

| Voltage Regulation | Off-load / On-load | On-load tap changer (OLTC) | Converter-controlled |

| Application Fields | Heat treatment, sintering, metal heating | Steel-making, smelting | Ferrous & non-ferrous melting |

| Customization | Supported | Supported | Supported |

Why Choose ZTelec Yuguang Furnace Transformers?

ZTelec Yuguang offers:

-

20+ years manufacturing experience

-

Full production line for oil-immersed furnace transformers

-

Support for up to 80 MVA custom furnace transformers

-

Global installations in steel plants, foundries, aluminum factories, heat-treatment plants

-

Fast delivery & international certification (IEC, CE, ISO, SASO, SONCAP, etc.)

Industrial furnace transformers—including resistance furnace transformers, arc furnace transformers, and induction furnace transformers—play a critical role in modern metallurgy and industrial heating. ZTelec Yuguang Transformer Factory provides reliable, customizable, and high-performance transformer solutions tailored to a wide variety of industrial furnace applications.

You may also find these interesting: