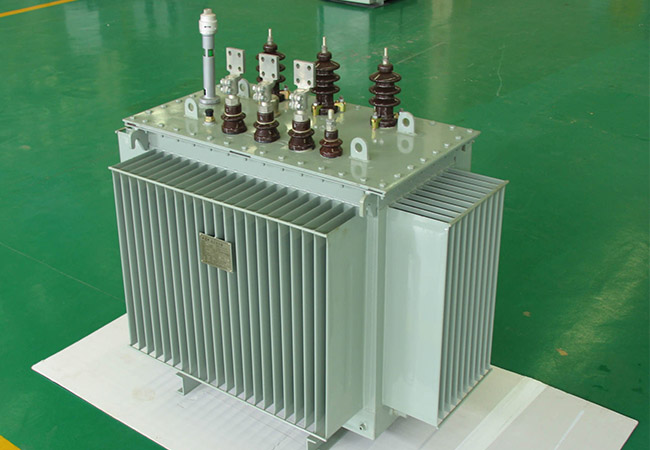

S11-M-250KVA/10/0.4kV oil immersed transformer

06-23 2025 | By:

S11-M-250KVA/10/0.4kV Oil-immersed Transformer

Performance and features of S11 type 10KV

The fully sealed power transformer uses the fins of the corrugated oil tank body as heat dissipation and cooling elements. The fins can expand and contract with the expansion and contraction of the transformer oil volume, thereby isolating the inside of the transformer from the atmosphere, preventing oil deterioration and insulation from moisture and aging. The core is made of high-quality cold-rolled oriented silicon steel sheets, which effectively improves the condition of magnetic flux density inside the core, reduces noise, and reduces losses. The coil is wound with high-strength enameled wire (or paper-wrapped wire), cylindrical (or pancake) structure, uniform ampere-turn distribution, reasonable insulation structure, and strong short-circuit resistance. The surface of the oil tank is phosphated and then three-proof (moisture-proof, mildew-proof, and salt spray-proof coating) is adopted, which is widely used in metallurgy, mining, petrochemical and other places with harsh use environment.

S13 10KV performance and features

S13 oil-immersed transformer is the energy-saving product with the best performance index of stacked core structure transformer. The S13 series products produced by our company use high-quality 0.23mm magnetic oriented silicon steel sheets. High and low voltage windings are all produced with copper foil and copper wire. The high voltage winding adopts a multi-layer cylindrical structure, which makes the ampere-turn distribution of the winding balanced, with small magnetic leakage, high mechanical strength and strong short-circuit resistance. The coil and core are vacuum dried, and the transformer oil adopts vacuum oil filtration and oil injection technology to improve the insulation strength inside the transformer. The new structural design and production process adopts the fully sealed corrugated sheet oil tank structure design and manufacturing, and the appearance is beautiful.

S11 35KV performance and features

The core adopts high-quality cold-rolled oriented silicon steel sheets, which effectively improves the condition of magnetic flux density inside the core, reduces noise and reduces losses. The coil is wound with high-strength enameled wire (or paper-covered wire), cylindrical (or pancake) structure, uniform ampere-turn distribution, reasonable insulation structure, and strong short-circuit resistance. The surface of the oil tank is phosphated and three-proof (moisture-proof, mildew-proof, and salt-fog-proof coating) is adopted, and it is widely used in metallurgy, mining, petrochemical and other places with harsh use environment.

Performance Parameters

| Rated capacity (kVA) | Voltagegroup | Vectorgroup | Loss (W) | No-load current (%) | Impedance voltage (%) | Boundan dimension (L×W×H,mm) | Weight (kg) | ||

| HV (kV) | LV(kV) | No-loadloss(W) | Loadloss(W) | ||||||

| 30 | 11 10.5 10 6 | 0.4 | Dyn11 or Yyn0 | 100 | 630/600 | 1.5 | 4 | 670×310×615 | 346 |

| 50 | 130 | 910/870 | 1.3 | 700×325×630 | 417 | ||||

| 80 | 180 | 1310/1250 | 1.2 | 755×355×690 | 556 | ||||

| 100 | 200 | 1580/1500 | 1.1 | 785×360×685 | 619 | ||||

| 125 | 240 | 1890/1800 | 1.1 | 805×370×720 | 703 | ||||

| 160 | 280 | 2310/2200 | 1.0 | 850×385×735 | 794 | ||||

| 200 | 340 | 2730/2600 | 1.0 | 865×405×805 | 935 | ||||

| 250 | 400 | 3200/3050 | 0.9 | 905×415×935 | 1086 | ||||

| 315 | 480 | 3830/3650 | 0.9 | 925×440×915 | 1226 | ||||

| 400 | 570 | 4520/4300 | 0.8 | 970×465×960 | 1468 | ||||

| 500 | 680 | 5410/5150 | 0.8 | 1035×500×1010 | 1758 | ||||

| 630 | 810 | 6200 | 0.6 | 4.5 | 1110×525×1075 | 2074 | |||

| 800 | 980 | 7500 | 0.6 | 1190×580×1155 | 2840 | ||||

| 1000 | 1150 | 10300 | 0.6 | 1205×560×1195 | 2842 | ||||

| 1250 | 1360 | 12000 | 0.5 | 1185×590×1205 | 3168 | ||||

| 1600 | 1640 | 14500 | 0.5 | 1225×565×1345 | 3800 | ||||

| 2000 | 1940 | 18300 | 0.4 | 5.0 | 1310×615×1435 | 4633 | |||

| 2500 | 2290 | 21200 | 0.4 | 1390×660×1510 | 5329 | ||||

You may also find these interesting: