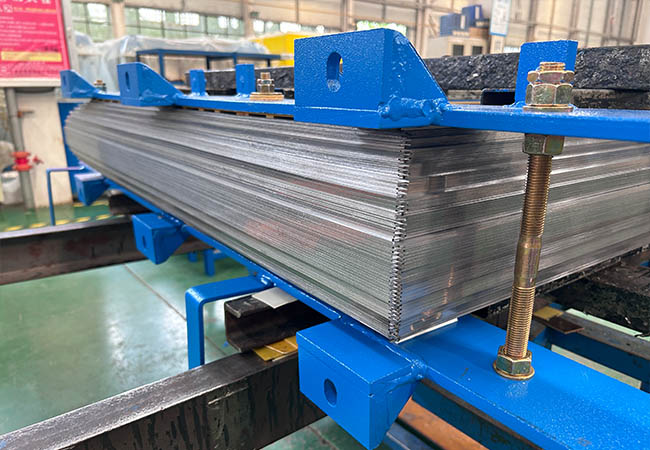

Stacked Lamination Core for Power Distribution Transformers, Reactors and Instrument Transformers

06-09 2025 | By:

Laminated Iron Core by ZTELEC Yuguang Electric Technology (Henan) Co., Ltd.

As a leading source manufacturer, ZTELEC Yuguang Electric Technology (Henan) Co., Ltd. specializes in producing high-performance laminated iron cores, tailored for distribution transformers, reactors, and instrument transformers. With advanced manufacturing facilities and strict quality control, our laminated iron cores are engineered to minimize eddy current losses and enhance magnetic permeability, ensuring optimal efficiency in electrical equipment. We proudly offer customized solutions to meet diverse technical requirements across global markets.

Technical Advantages of Laminated Iron Cores

Our laminated iron cores feature precision-cut silicon steel sheets with insulated coatings, reducing hysteresis and eddy current losses by up to 30% compared to solid cores. The laminations are stacked in a step-lap configuration to minimize magnetic flux leakage, enhancing the core’s magnetic conductivity and reducing noise levels. This design also allows for easier heat dissipation, extending the service life of electrical equipment in continuous operation.

Applications in Electrical Equipment

- Distribution Transformers: Ideal for 10kV-35kV power distribution systems, our cores enable transformers to achieve high efficiency (up to 99.5%) and low no-load losses, complying with international standards like IEC 60076 and ANSI C57.

- Reactors: Used in harmonic filtering and reactive power compensation systems, the cores maintain stable inductance under varying load conditions, ensuring grid stability.

- Instrument Transformers: For voltage and current transformers, our cores provide excellent linearity and low excitation current, ensuring accurate measurement and protection relay operation.

Below is a detailed table outlining the specifications, parameters, and application scenarios of our laminated iron cores:

|

Parameter

|

ZT-LC-10

|

ZT-LC-20

|

ZT-LC-30

|

ZT-LC-50

|

|

Core Material

|

30Q120 Silicon Steel

|

35Q145 Silicon Steel

|

30Q130 Silicon Steel

|

27Q120 Silicon Steel

|

|

Lamination Thickness

|

0.30mm

|

0.35mm

|

0.30mm

|

0.27mm

|

|

Stacking Factor

|

≥0.97

|

≥0.96

|

≥0.97

|

≥0.98

|

|

Core Type

|

Distribution Transformer

|

Distribution Transformer

|

Reactor

|

Instrument Transformer

|

|

Rated Power Range

|

50-250kVA

|

250-1000kVA

|

100-500kVar

|

–

|

|

Voltage Class

|

10kV

|

10-35kV

|

10-35kV

|

10-35kV

|

|

Flux Density (at 50Hz)

|

1.5T

|

1.6T

|

1.4T

|

1.3T

|

|

Loss Density (at 1.5T/50Hz)

|

≤1.2W/kg

|

≤1.5W/kg

|

≤1.0W/kg

|

≤0.8W/kg

|

|

Noise Level (at 1m)

|

≤45dB

|

≤48dB

|

≤42dB

|

≤38dB

|

|

Insulation Class

|

Class F/H

|

Class F/H

|

Class F

|

Class H

|

|

Application Scenarios

|

Urban distribution networks, commercial buildings

|

Substations, industrial parks

|

Harmonic filtering systems, renewable energy grids

|

High-precision measurement systems, relay protection

|

|

Customization Options

|

Core size, lamination coating, stacking configuration

|

Core geometry (circular/rectangular), noise reduction treatment

|

Inductance tolerance control, corrosion-resistant coating

|

Low-loss design for metering applications

|

Customization Capabilities

As a source manufacturer, we offer comprehensive customization services:

- Material Selection: Options from low-loss 23Q095 to high-permeability 35A300 silicon steel grades

- Core Geometry: Circular, rectangular, or three-phase five-limb configurations

- Special Treatments: Anti-corrosion coatings for coastal environments, vacuum impregnation for low-noise requirements

- Testing Services: Magnetic property testing, loss measurement, and temperature rise analysis

ZTELEC Yuguang’s laminated iron cores are used in projects across Southeast Asia, Europe, and Africa, supporting reliable power distribution in urban grids, renewable energy plants, and industrial complexes. Our technical team collaborates closely with clients to optimize core designs for specific applications, ensuring maximum efficiency and cost-effectiveness.

For detailed technical datasheets, sample requests, or custom project inquiries, please contact our sales team. We are committed to delivering premium iron core solutions that drive innovation in electrical equipment manufacturing.

You may also find these interesting: