Advantages and Disadvantages of Dry-Type Transformers and Oil-Immersed Transformers

10-22 2024 | By:

Advantages and Disadvantages of Dry-Type Transformers and Oil-Immersed Transformers

Dry transformers are more expensive than oil transformers in terms of price.

In terms of capacity, large-capacity oil transformers are more than dry transformers.

Dry transformers are required in complex buildings (basements, floors, rooftops, etc.) and crowded places. Oil transformers are used in independent substations.

Box transformers are generally used for transformers in box transformers. Oil transformers are generally used for temporary outdoor power supply.

Dry transformers and oil transformers are selected according to the space during construction. Oil transformers can be selected when the space is large, and dry transformers can be selected when the space is crowded.

Oil transformers are easy to use in areas with humid and hot climates. If dry transformers are used, forced air cooling equipment must be provided.

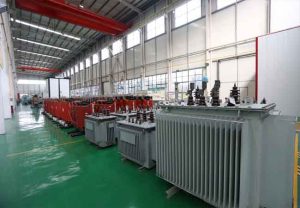

ztelecgroup oil transformer

1. Appearance

The packaging form is different. The core and coil can be seen directly in the dry-type transformer, while only the shell of the transformer can be seen in the oil-type transformer;

2. Different lead forms

Most dry-type transformers use silicone rubber bushings, while most oil-type transformers use porcelain bushings;

3. Different capacity and voltage

Dry-type transformers are generally suitable for power distribution, with a capacity of less than 1600KVA and a voltage of less than 10KV. Some of them can reach a voltage level of 35KV; while oil-type transformers can reach all capacities from small to large, and the voltage level can also reach all voltages; the UHV 1000KV test line being built in the mainland must use oil-type transformers.

4. Different insulation and heat dissipation

Dry-type transformers are generally insulated with resin, cooled by natural air, and large-capacity by fans, while oil-type transformers are insulated by insulating oil, and the heat generated by the coil is transferred to the radiator (sheet) of the transformer for heat dissipation by the circulation of insulating oil inside the transformer.

5. Applicable places

Dry-type transformers are mostly used in places that require “fire prevention and explosion prevention”, and are generally easy to use in large buildings and high-rise buildings; while oil-type transformers may have oil spraying or leakage after “accidents”, causing fires, so they are mostly used outdoors and in places where there are sites to dig “accident oil pools”.

6. Different load bearing capacity

Generally, dry-type transformers should operate at rated capacity, while oil-type transformers have better overload capacity.

7. Different costs

For transformers of the same capacity, the purchase price of dry-type transformers is much higher than that of oil-type transformers.

The model of dry-type transformer generally starts with SC (epoxy resin casting encapsulation type), SCR (non-epoxy resin casting solid insulation encapsulation type), SG (open type)

- SCB10 dry type transformer

- Step Up Three Phase 33kV Outdoor Oil Immersed Transformer

- S11-M series transformer

Differences between dry-type transformers and oil-immersed transformers

“Of course, the same thing is that they are all power transformers, and they all have iron cores for magnetic circuits and windings for circuits. The biggest difference is “oil type” and “dry type”. That is to say, the cooling medium of the two is different. The former uses transformer oil (of course there are other oils such as β oil) as cooling and insulation medium, and the latter uses air or other gases such as SF6 as cooling medium. Oil transformers are the body composed of iron core and windings placed in an oil tank filled with transformer oil. Dry transformers often cast and encapsulate the iron core and windings with epoxy resin. There is also a non-encapsulated type that is now more commonly used. The windings are made of special insulating paper and then impregnated with special insulating paint to prevent the windings or iron cores from getting wet. (Because the two are derived from different categories due to different classification methods in terms of process, use, and structure, we will discuss them from a narrow perspective. =In terms of output and usage, the current voltage level of dry transformers is only 35kV, and the capacity is smaller than that of oil transformers, about 2500kVA. In addition, the manufacturing process of dry transformers is more complicated and the cost is higher than that of oil transformers of the same voltage level and capacity. Therefore, oil transformers are still more used in terms of usage. However, due to the environmental protection, flame retardancy, impact resistance and other advantages of dry transformers, they are often used in high-demand power supply and distribution places such as indoors, such as hotels, office buildings, high-rise buildings, etc. If you are just a transformer user, it should be enough to understand these.

Each has its own advantages and disadvantages. Oil transformers are low in cost and easy to maintain, but they are flammable and explosive. Due to their good fire resistance, dry transformers can be installed in the load center area to reduce voltage loss and power loss. However, dry transformers are expensive, large in size, poor in moisture and dust resistance, and noisy.

Oil transformers are gradually withdrawn, and dry transformers are used. Dry transformers can be disassembled for transportation and storage, and are easy to clean and maintain. They do not require a base for installation and have no oil seepage pool. They are relatively easy to distinguish from the outside; the biggest difference between oil-immersed transformers and dry-type transformers is whether there is “oil”. Since oil is a liquid and has fluidity, oil-immersed transformers must have an outer shell, and the inside of the outer shell is transformer oil. The transformer coil is immersed in the oil, and the transformer coil cannot be seen from the outside; dry-type transformers do not have oil, so there is no need for an outer shell, and the transformer coil can be seen directly; another feature is that there is an oil pillow on the oil-immersed transformer, and the transformer oil is stored inside, but now new oil-immersed transformers are also produced without oil pillows; in order to facilitate heat dissipation, that is, to facilitate the flow and heat dissipation of the internal insulating oil, the oil-immersed transformer is designed with a radiator on the outside, just like a heat sink, while the dry-type transformer does not have this radiator. The heat dissipation depends on the fan under the transformer coil. The fan is a bit like the indoor unit of a household air conditioner;

Due to the need for fire protection, oil-immersed transformers are generally installed in a separate transformer room or outdoors, while dry-type transformers must be installed indoors, generally in the low-voltage distribution room, and installed side by side with the low-voltage distribution cabinet.

You may also find these interesting: