Phase-shifting rectifier transformer for high-voltage frequency converter

06-03 2025 | By:

Phase-shifting rectifier transformer for high-voltage frequency converter

1. Overview

High-voltage variable frequency speed regulation technology has developed rapidly in recent years. In today’s world where energy is scarce and environmental problems are becoming increasingly serious, energy conservation and emission reduction have already had quantitative assessment indicators. The speed regulation mode of medium-voltage motors has been changed to variable frequency speed regulation, which has been promoted as a general energy-saving technology in the 11th Five-Year Plan. The relationship between the motor speed n and the power supply frequency f, slip rate s, and motor pole pair number p is n=60f(1-s)/p. Since there is a linear relationship between n and f, this speed regulation has the characteristics of stepless and wide range, and there is no power loss caused by excitation slip and throttling during the speed regulation process. According to statistics, 1/3 of the motor power loss can be saved through variable frequency speed regulation. High-voltage variable-frequency speed regulation technology is currently diversified. The cascade multiplexing technology represented by Siemens (formerly ASIRobicon) technology can basically achieve perfect harmonic-free. It uses a rectifier transformer to superimpose (connect in series) multiple low-voltage modules to form a high-voltage output. The power device uses IGBT. At present, most domestic high-voltage inverter manufacturers use this technology, including Japan’s Toshiba, Mitsubishi, Hitachi, etc. ABB’s ACS5000 series inverter is a three-level topology structure. The 36-pulse rectifier transformer has a total of 6 phase shift groups, and each two phase shift groups supply power to a frequency conversion unit. The power device is IGCT. ABB also has an inverter that uses 12-pulse rectifier inverter technology, and its transformer uses a three-winding form. The 18-pulse rectifier inverter technology represented by AB (Rockwell) is different from ASIrobicon and ABB in that it requires the rectifier transformer to adopt a three-split form.

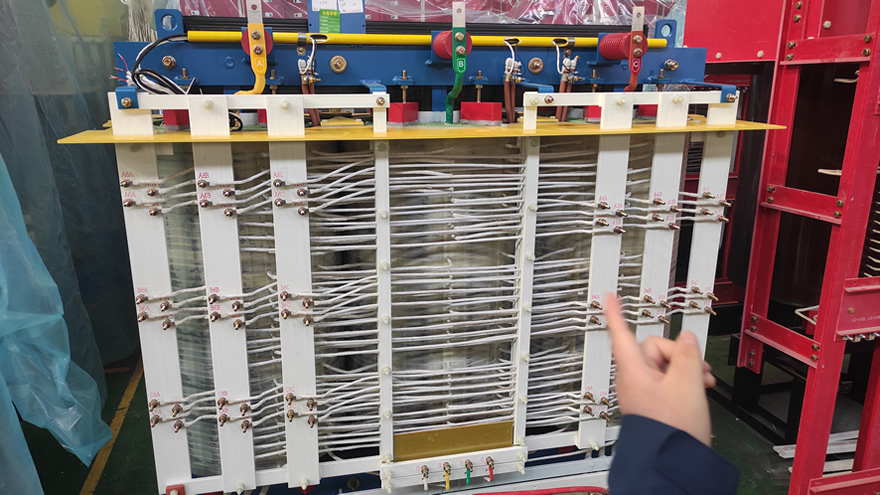

2. H-class dry-type rectifier transformer is more suitable for high-voltage inverters. High-voltage inverters are a complete set of equipment, consisting of transformer unit cabinets, power unit cabinets, control unit cabinets, and some also have bypass cabinets. Since the transformer is placed in the cabinet, the transformer needs to have a high heat resistance level, good heat dissipation, and strong overload capacity. The temperature resistance level of the H-class dry-type rectifier transformer is 180C, and the main insulating material is Nomex paper, which is a patented product of DuPont in the United States. It is a synthetic insulating material based on aromatic amide fiber. It is C-class and has a temperature resistance of 220C. Nomex paper has many advantages. It is an excellent electrical insulating material. The transformer made of it can be moisture-proof, flame-retardant, and has good environmental adaptability. In addition, the transformer is compact in size and occupies a small space. The transformer’s resistance to cold and heat shock, short circuit resistance, and overvoltage resistance are better than other types of transformers. In particular, the manufacturing process and product structural characteristics of H-class rectifier transformers have very obvious advantages for rectifier transformers that require multiple taps and complex structures with multiple phase-shifting windings, which shortens the manufacturing and processing cycle and reduces the cost. After vacuum pressure impregnation (VIP), the winding has good rigidity and mechanical strength is guaranteed. At the same time, due to the paint film covering the surface of the insulating material, the moisture resistance of the transformer is improved.

3. Multiplexing technology is realized through transformers

The perfect harmonic-free inverter forms a phase difference between each secondary winding through multiple phase-shifting groups of the rectifier transformer. Each phase-shifting group supplies power to the corresponding power unit to achieve input multiplexing, complete rectification, inversion, and frequency conversion in these units, and then superimpose them. With multiple phase shifting, the pollution of the harmonics generated by each unit to the power grid can be eliminated. This is the basic working principle of the perfect harmonic-free inverter. As an important component of this technology, the rectifier transformer appeared and developed rapidly along with the technology of high-voltage inverters. According to the number of inverter units and voltage levels, the number of output windings and voltage of the phase-shifting rectifier transformer are also different. 3kV mostly adopts 3 levels, the phase shift is divided into 0° and +20°, and the voltage of each phase shift group is 630V; 6kV mostly adopts 6 levels, the phase shift is divided into +5°, +15°, ±25°, and the voltage of each phase shift group is 630V. There are also 5 or 7 levels. When the 5-level phase shift angle is 0°, ±12°, ±24°, the voltage is 710V, and when the 7-level phase shift angle is 0°, ±8.57° ±17.14°, ±25.71°, the voltage is 490V; 10kV mostly adopts 8 levels, the phase shift is divided into ±3.75°, ±11.25°, ±18.75°, ±26.25°, and the voltage of each phase shift group is 720V. There are also 9 and 10 levels. Theoretically, the more stages there are, the fewer harmonics there are on the transformer input side, and the less pollution there is to the power grid. However, the more stages there are, the more power units there are in the inverter, which increases the manufacturing cost. Therefore, the above stages are generally adopted by inverter manufacturers. The transformer required by ABB’s ACS5000 inverter is simpler in structure than the above ones; 12-pulse and 18-pulse rectifier transformers are mostly split.

You may also find these interesting: