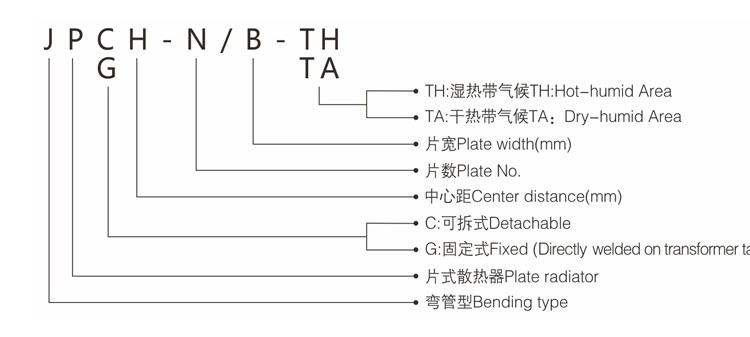

Transformer Heat Sinks Customized

Product Overview

Flat radiators are widely used both domestically and internationally as cooling components for oil-immersed transformers.

Our products utilize high-quality cold strips to create fully corrugated plates, which are then joined, spot-welded, and seam-welded into a single plate. The plates are connected to the collector using CO2 gas shielded welding, completely eliminating the defects of internal welding that can produce slag and iron filings, which can seriously impact the quality of the transformer. These products undergo rigorous sealing inspection, surface treatment, and hot oil flushing to fully guarantee product quality.

All technical specifications of this product fully meet the requirements of JB/T5347-1999, the “Industry Standard for Laminated Radiators for Transformers.”

Scope of Application

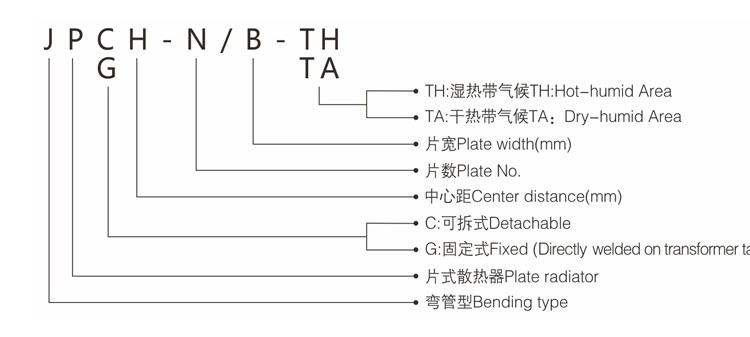

This radiator is a specialized cooling device for large and medium-sized power transformers, reactors, and other products. It can be directly connected to the transformer tank flange or mounted independently on a bracket near the transformer. The radiator complies with the JB15347-2013 standard.

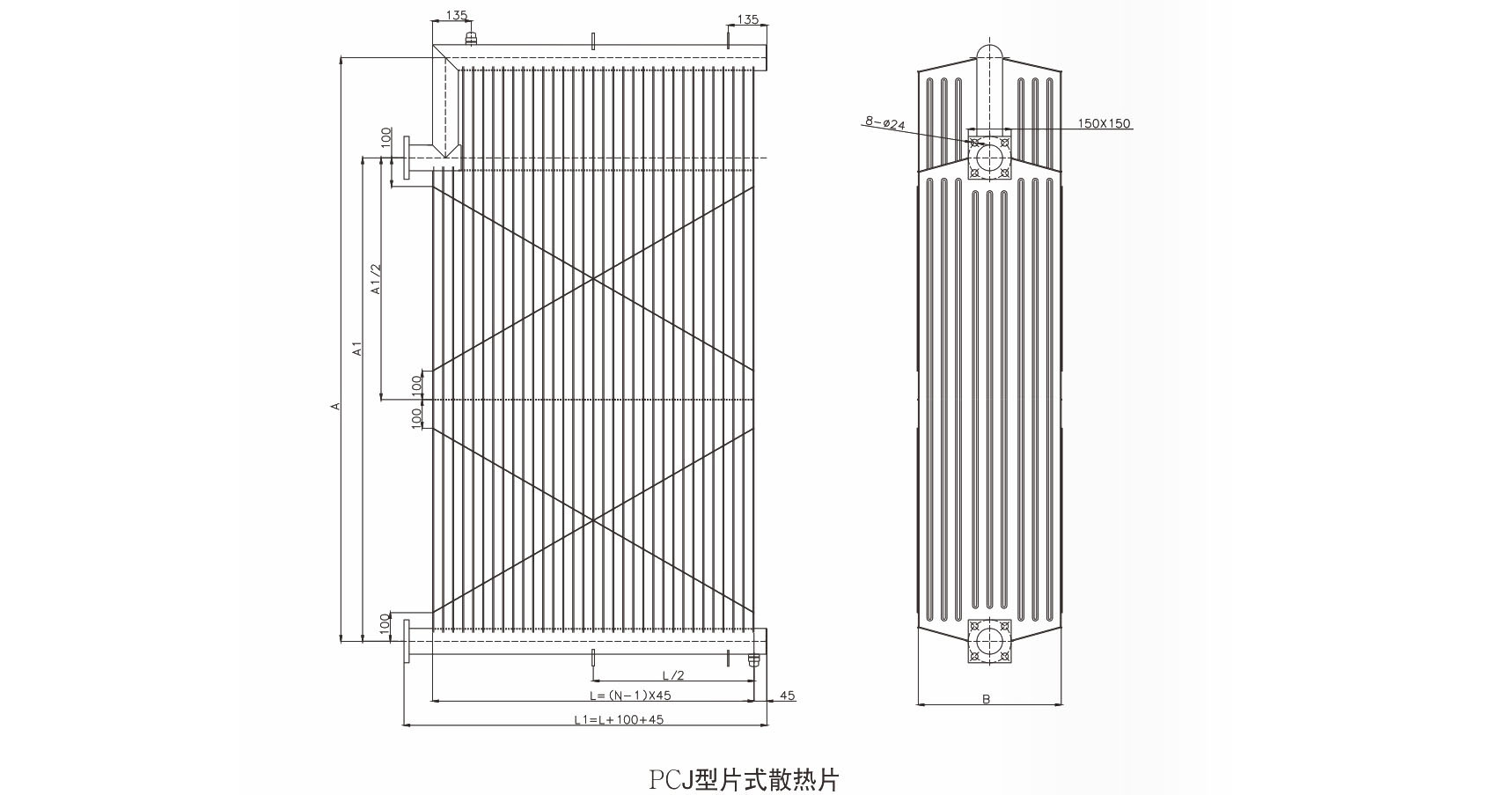

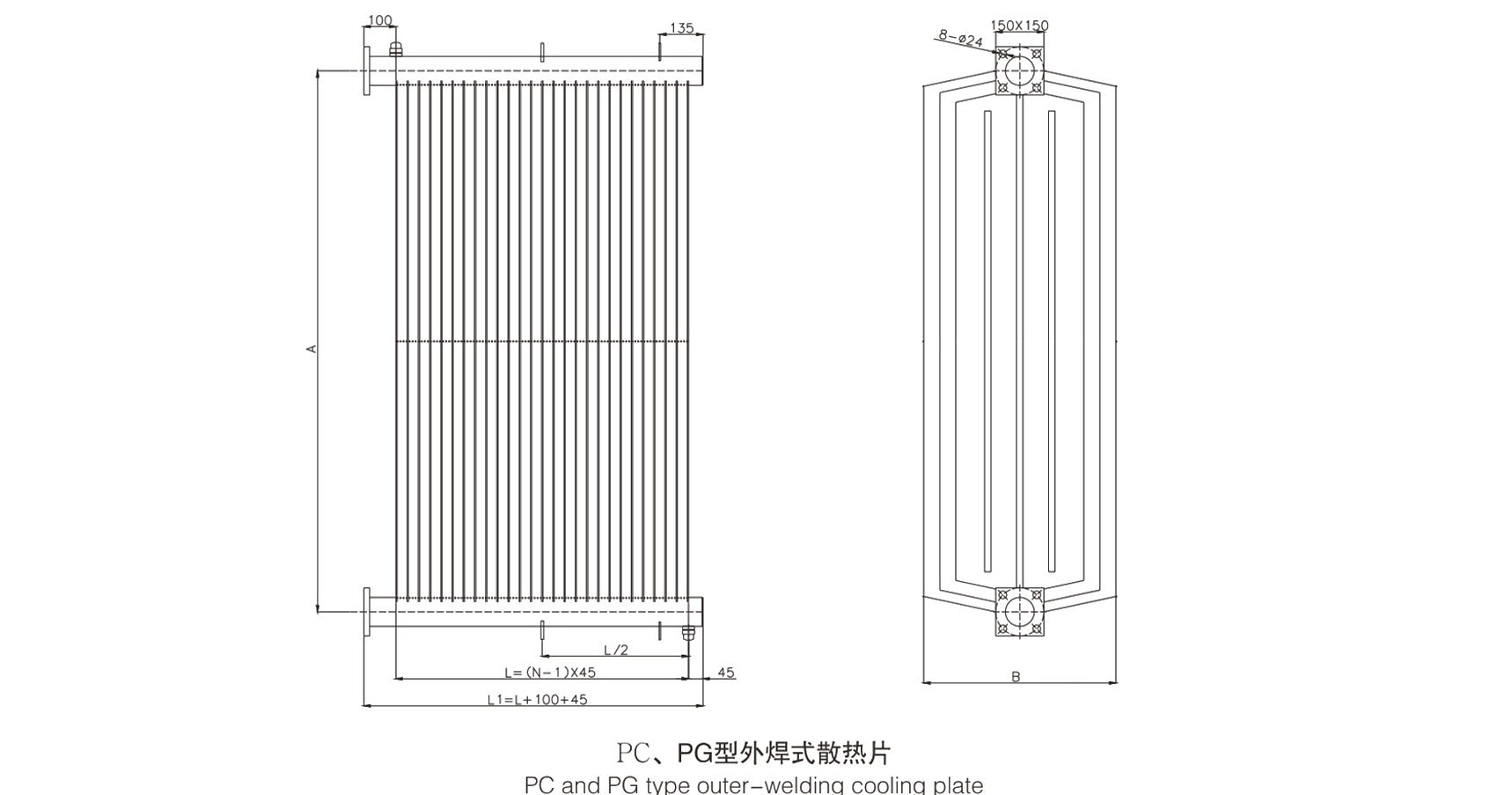

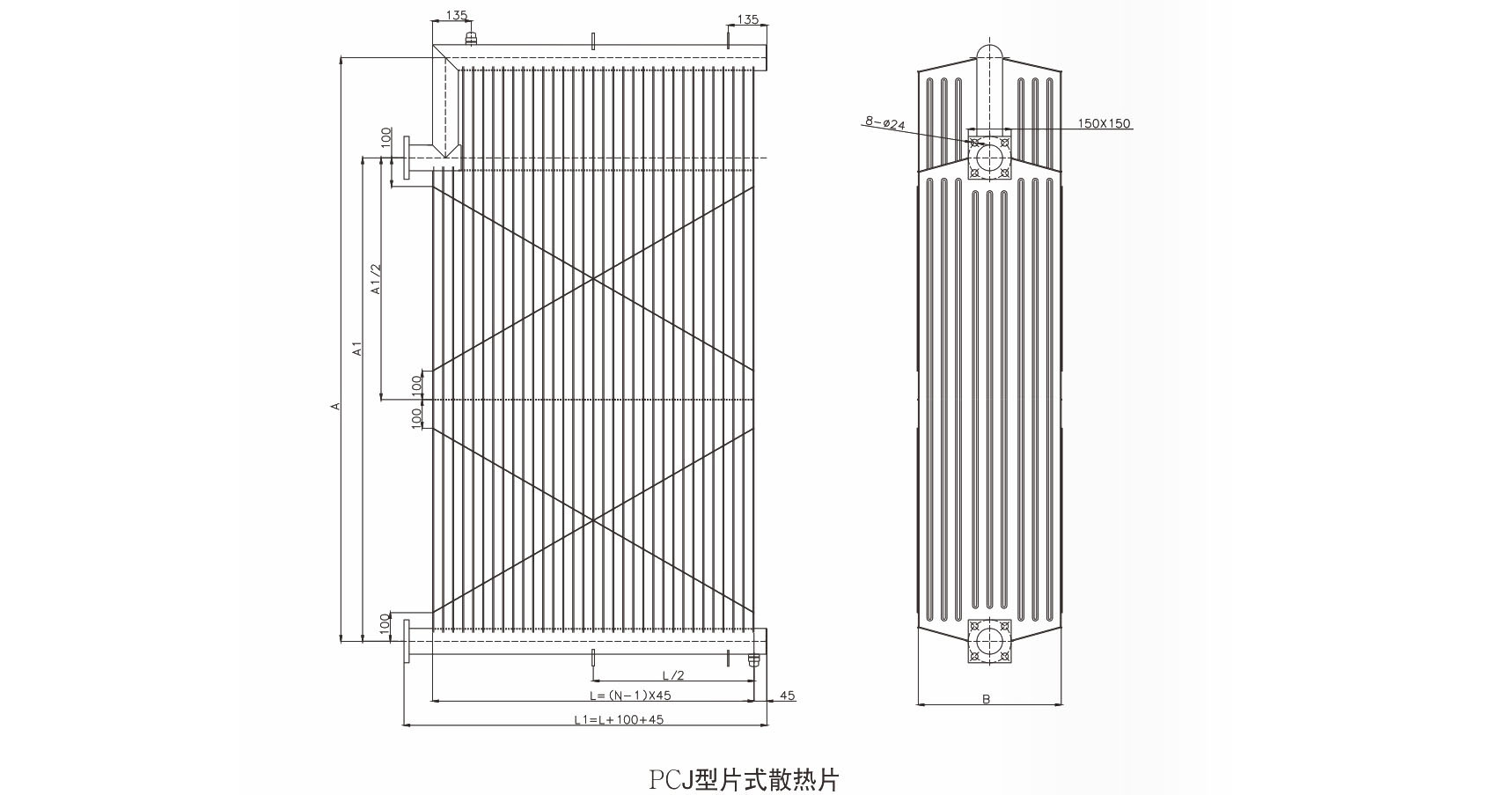

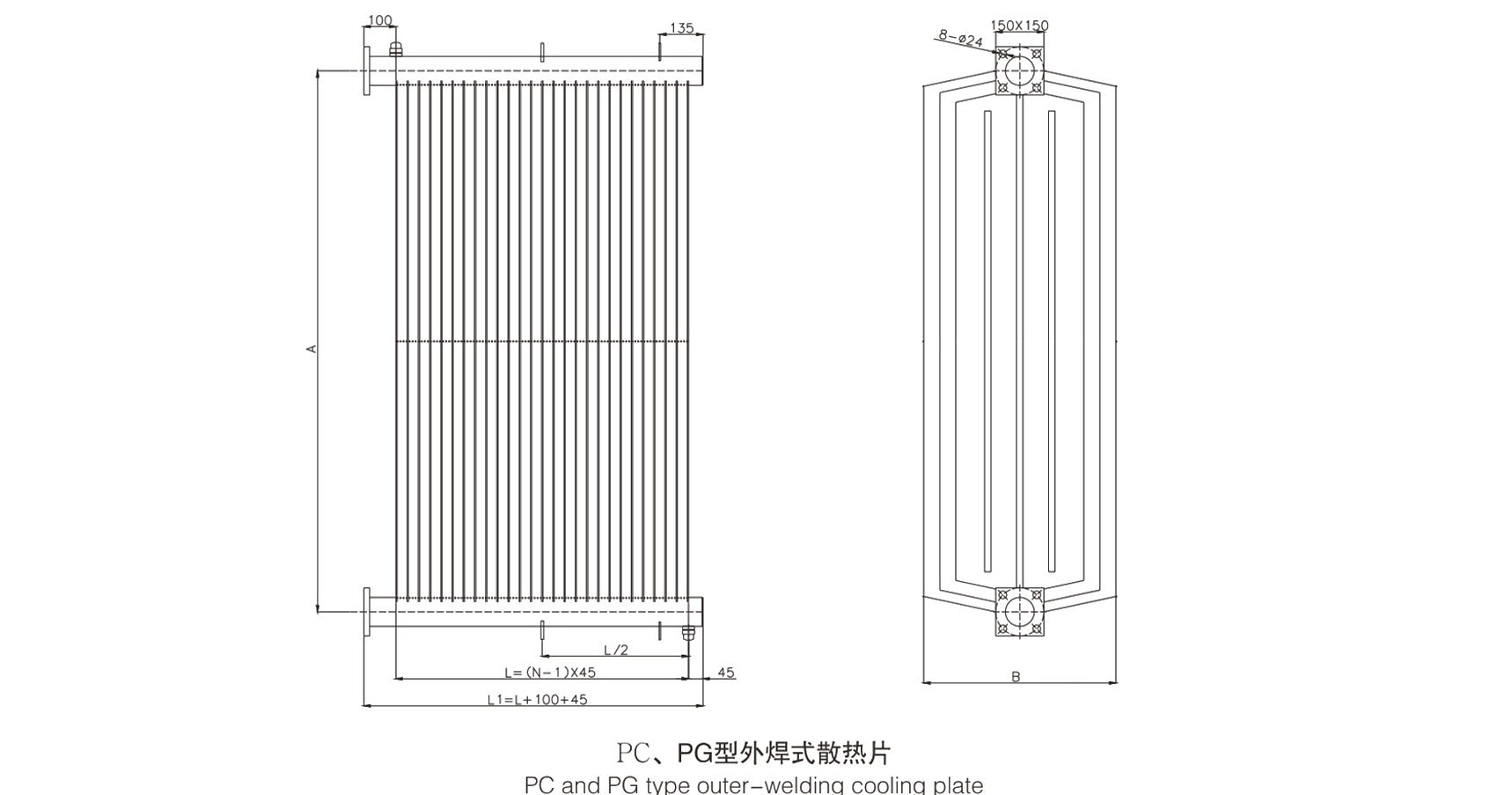

Transformer Radiator Widths: 310mm, 480mm, 520mm, 535mm

Transformer Radiator Center Distance: 500-4200mm

Type: PC/PG

Material: Cold-rolled steel, Cold-rolled steel plate

Model: Radiator

Fin Thickness: Custom

Pitch: 40, 45, 50mm (Customized)

Color: Gray(Customized)

Transformer Heat Sinks

Cooling Methods:

a. Self-cooling: The radiator dissipates heat through natural convection.

b. Air-cooling: The radiator dissipates heat through a fan (bottom or side blow).

c. Forced Oil-Air Cooling: The radiator circulates oil through a pump and uses a fan to dissipate heat. Marking, Packaging, Transportation, and Storage:

All products are accompanied by a quality certificate and a certificate of conformity, clearly indicating the model, specifications, inspector, and production date. They must be securely packed in wooden packaging for easy transportation. The headers are securely capped with plastic covers. Radiators should be stored in a location protected from rain, moisture, corrosion, and mildew. Do not remove the covers before use. For PC-type radiators, a steel cover plate may be used upon request.

Transformer Heat Sinks

Installation and Use:

1. Remove the header caps before installing the radiator. When installing a detachable radiator, ensure the upper and lower headers are separated as shown in Figure 2.

2. The spacing between radiators should not be less than 50 mm. The center of the lower header should be at an appropriate height from the ground to facilitate air circulation.

3. Installation of fixed radiator: according to the outer diameter of the manifold, make a hole on the side wall of the transformer oil tank and weld the radiator directly to the outside of the oil tank. Welding should be done on the outside of the oil tank and never on the inside to prevent foreign matter such as welding slag from entering the radiator.

4. Installation of detachable radiator:

(1) Please match the flange interface on the transformer oil tank according to the selected radiator center distance, radiator group spacing and flange size, and select appropriate rubber gaskets, bolts, nuts and washers. Similarly, match the plate, nuts, bolts and washers according to the group spacing and the ①14 long hole in the radiator connection plate.

(2) When installing, lift the radiator with a hook, align the upper and lower flanges, pad the gasket, tighten the fixing bolts, and fix the adjacent radiators with a pull plate.

(3) When filling the oil, tighten the oil drain plug and open the air bleed plug. When oil overflows from the air bleed hole, tighten the air bleed plug again.

(4) When using bottom-blown air cooling, the lower manifold has a bracket for hanging fans (self-cooling type does not have a bracket). One fan is hung for every two radiator groups. When the number of radiator groups on the same side is odd, please arrange the dimensions according to Figure 4. (The fan bracket can be prepared according to user requirements)

(5) When using side-blown air cooling, please install and fix the fan in an appropriate position on the transformer oil tank. VI. Precautions: (1) During transportation, installation, and flushing, be careful not to touch or damage the oil channel of the heat sink. (2) If a sealing test is required before installation, the test pressure (internal pressure) shall not exceed 0.12MPa (i.e. 1.2 standard atmospheric pressure).