Copyright © 2022 hnztelec. All rights reserved.

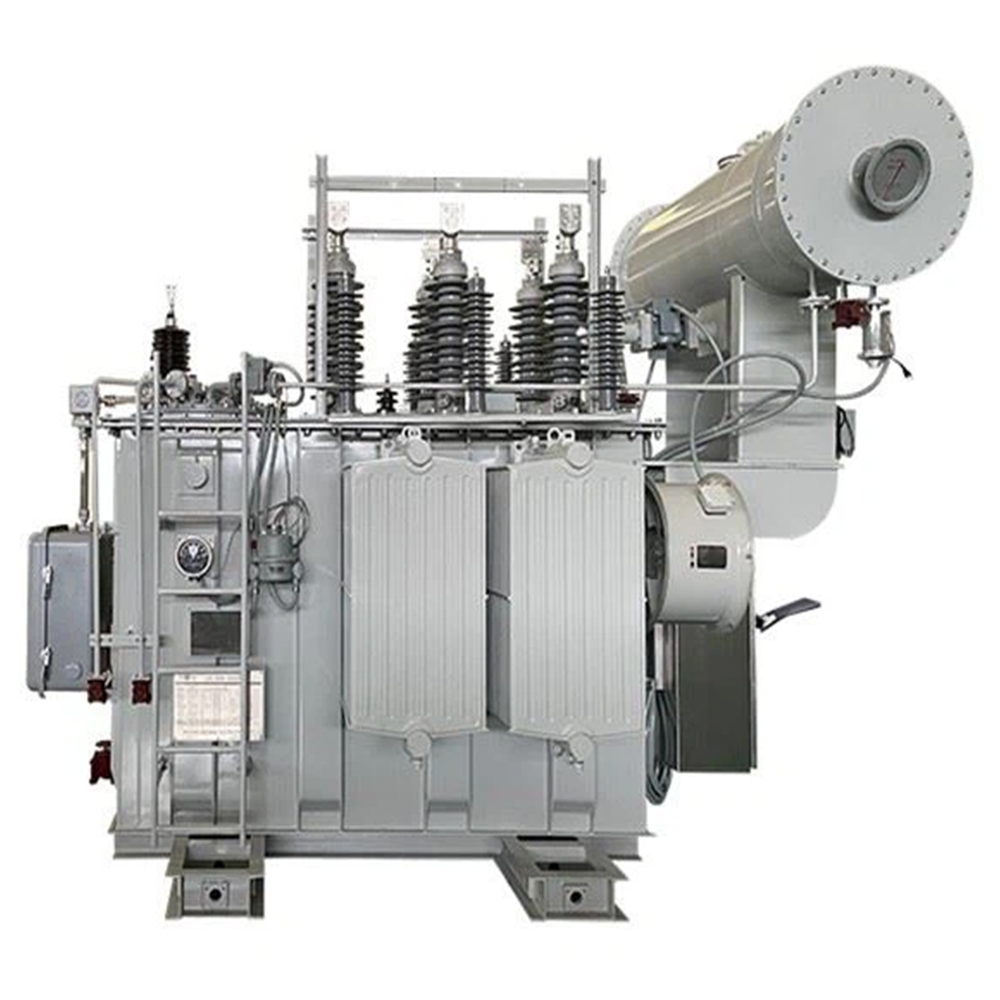

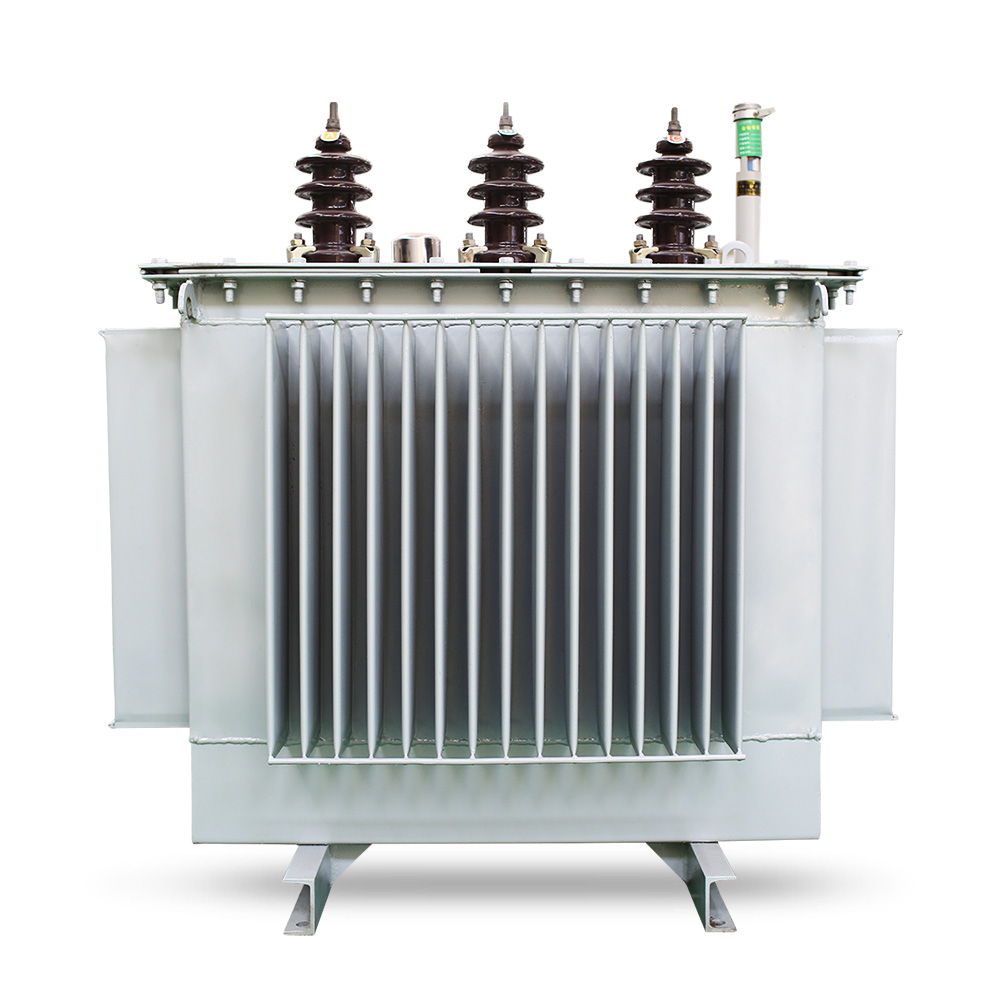

35kV rectifier transformer for silicon carbide and graphite electric furnace

| Rated voltage | 6/10/35/110kv |

|---|---|

| Rated capacity | 1000kVA-31.5MVA |

| Application scenarios | Metallurgical Furnace Systems,Silicon Carbide Production.Graphite Electric Furnaces,Industrial Power Retrofit |

| Certifications & Standards | Industrial Power Retrofit |