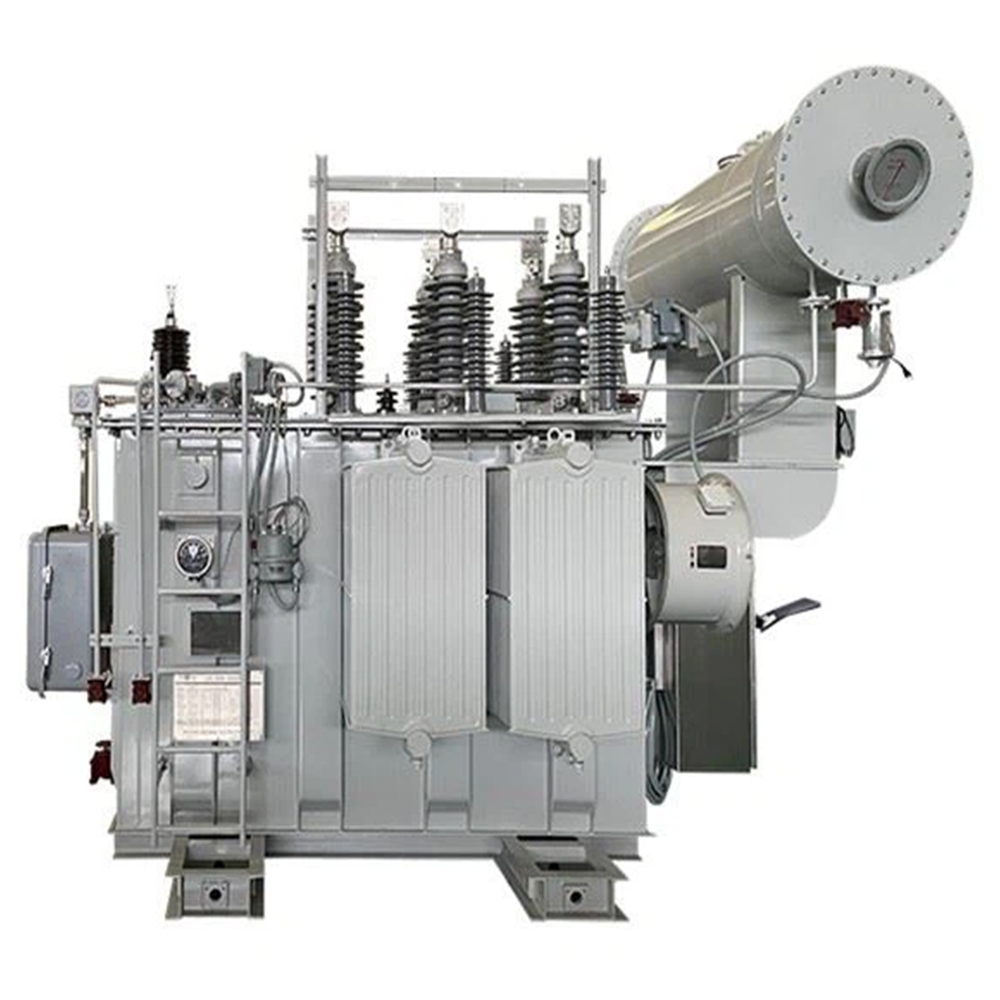

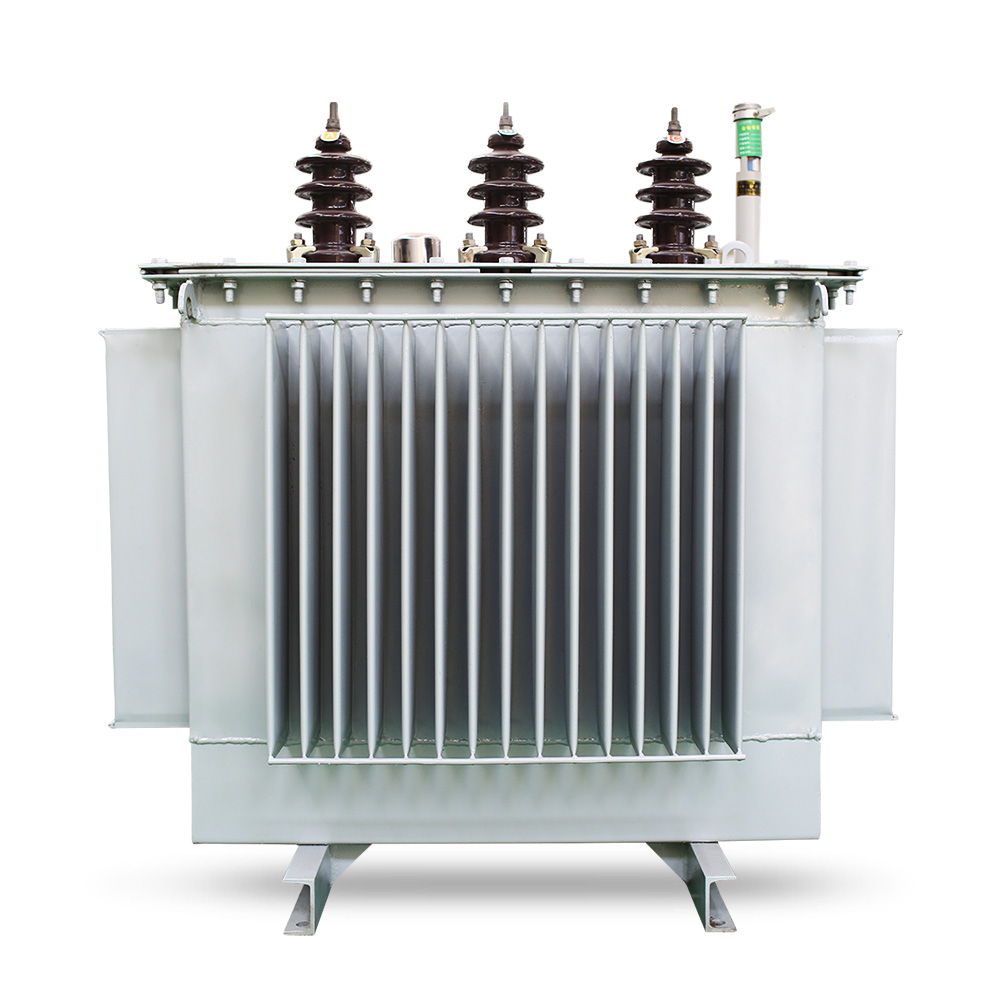

6KV 10KV 35KV On-load Voltage Regulator Auto Transformer

Product Features

(1) Using auto-transformer structure, can be achieved within ±20% automatic voltage regulator with load;

(2) With excellent performance and communications capabilities,realizing “four remote” function: telemetering, remote letter, remote harmony remote control.

(3) Using a unique anti-jamming measures, ensure normal controllers work;

(4) The controller is equipped with high and low limit protection to prevent tap-changer jammed;

(5) The on-load tap-changers and auto-transformer tank the tank isolation;

(6) Small size, light weight, large capacity, low loss and easy to install;

(7) Having a significant effect of reducing consumption and energy conservation;

(8) The high performance, high reliability.

Working Principle

SVR circuit automatic voltage regulator has three parts: the auto-transformer, on-load tap-changer and automatic control devices.

Auto-transformer of the coils is divided into three parts: the electromagnetic coils, static coils, control coils. In which, series Reed coil is a has multiple tapped of winding, these tapped through has contains points received switch of different contact series in entered and output , change points received location, to change automatically transformer variable than, reached high-speed voltage of purpose; and Reed coil for since coupling transformer of public winding, produced passed energy of magnetic field; control coil for controller provides work power and sampling signal.

On-load tap- changer, is in the case of load transfer contact switches. Automatic voltage regulator in the series winding tapped in on-load tap changer on a different point, you can transfer contact to change its output voltage regulating transformer. Consider the on-load tap-changer service life precision and user adjustable pressure, commonly uses don-load tap changer in the stalls for 7 and 9.

Automatic controller is the core of the entire unit, which is mainly composed of single-chip microcomputer control chip,show, keys and voltage sampling and current sampling, State input, communication port, the control output circuit, data storage and other circuit components, applications, computer technology, electronics technology, using military-grade control chip, high reliability, strong anti-jamming ability can adapt to outdoor harsh environments. Mining and P0-P1-P2and C1,C2 current signal voltage signal and then compare with the setting in the program: exceeds the set limit,directives control the on-load tap-changer up; lower limit exceeds the set value, control of on-load tap-changer down directives issued, regulating operation.

Using Environment

| Description |

Unit |

Using Environment |

| Altitude |

m |

≤2000 |

| Ambient air temperature |

Max temperature |

ºC |

+40 |

| Min temperature |

-40 |

| Wind speed |

m/s |

≤35 |

| Pollution class |

|

IV |

| Seismic acceleration |

Horizontal |

m/s² |

≤3 |

| Vertical |

m/s² |

≤1.5 |

| Security coefficient |

|

>1.67 |

Technical Parameters of Voltage Regulator & Automatic Specifications

| Description |

Unit |

Technical Parameters |

| Rated voltage |

KV |

6,10,35 |

| Rated capacity |

6KV |

KVA |

500-5000 |

| 10KV |

315-12500 |

| 35KV |

500-24000 |

| Rated frequency |

Hz |

50/60 |

| Connection modes |

|

Star connection of three-phase three-wire single-winding |

| Tap series |

|

7 / 9 |

| Type of cooling |

|

Oil-immersed natural cooling |

| Adjustable range |

|

– 10% ~ + 10%/

-5% ~ + 15%)/

0 ~ +20% |

| Power supply |

V |

100~260 (AC/DC, 50Hz) |

| Analogue |

2 Channel |

0~220V |

| 1 Channel |

0~5A |

| 1 Channel |

platinum resistance fuel input |

| Switch value |

Input |

20 Channel |

| Output |

6 Channel |

| Measuring accuracy |

|

0.5 |

| Interference level |

|

IEC6 10004: 1995 IV |

(lf you have special requirements please specify when ordering.)

Wellness Checks on the SVR

(1) Within the rated load current, with or without drastic changes, the operating voltage is normal;

(2) The oil level, oil color, oil temperature exceeds the permitted value, there is no oil leakage phenomenon;

(3) Ceramic casing is clean and there are no cracks, damage or stains, discharge, whether the Terminal has color,contact overheating;

(4) Wet silicone is a saturated color, SVR running sound is normal;

(5) If air in the gas relay, filled with oil, the oil level gauge whether glass has broken;

(6) The SVR shell, arrestor grounding is good, oil valve is working correctly.

SVR Periodic Testing and Maintenance

(1) Performance indicators such as oil analysis—pressure once every three years;

(2) The insulation resistance is not less than the original value of 70%, the DC resistance of windings at the same temperature, the phase difference between the average is less than 2%, and compared with the results of previous measurements should not be more than 2%;

(3) Power failure cleaning and inspection cycle, determined according to the surrounding environment and loading conditions, generally six months to one year; main contents are: removal of deficiencies found during an inspection, the porcelain bushing shell cleaned, broken or aging pads replaced, tighten connection points check, oil fill oil, respirator silicone check replacement;

4) Operation and maintenance of on- load tap-changer:

A, Tap years total action in 5,000 times or average movements at around 14 times ,the number of days per year should take the tap switch box oil pressure test; tap action frequently is recommended every six months to take tap the oil in the tank pressure test;

B, Running the on-load tap-changer insulating oil breakdown voltage is less than 25kV, oil filter or replace the tap should be the insulating oil in the tank.

Simple fault analysis and removal

A, If the body of oil:

1. Using clean cloth, wipe clean parts of the oil;

2. Carefully observe the bushing, pressure relief valve, oil level gauge, temperature sensor and whether the transport screw loosening caused by vibration;

3. Fastening parts.

B, After the transmission, if controller without display:

1. Power switch not turned on, please turn on it;

2. Power source fusing or fuse fusing, please replace (2A/250V, spare parts inside the control box);

3.The secondary connector is loose, please check and tighten.

Some Specifications Overall Dimensions and Weight

(for Reference only,subject to the actual weight ,dimension and drawing.)

| Rated Capacity(KVA) |

Overall Dimensions(mm)

(length x width x height ) |

Track Gauge(D:mm) |

Total Weight(kg) |

| 315 |

1600 x 800 x 1080 |

660 x 660 |

800 |

| 500 |

1670 x 860 x 1190 |

660 x 660 |

990 |

| 1000 |

1800 x 950 x 1290 |

660 x 660 |

1320 |

| 2000 |

2090 x 1060 x 1460 |

660 x 660 |

1920 |

| 3000 |

2360 x 1150 x 1960 |

820 x 820 |

2720 |

| 4000 |

2500 x 1290 x 2090 |

820 x 820 |

4100 |

| 5000 |

2640 x 1480 x 2200 |

820 x 820 |

4800 |

| 6300 |

3300 x 1900 x 2520 |

1070 x 1070 |

6500 |

| 8000 |

3900 x 3400 x 2680 |

1070 x 1070 |

8100 |