Power Transformer Oil Tank

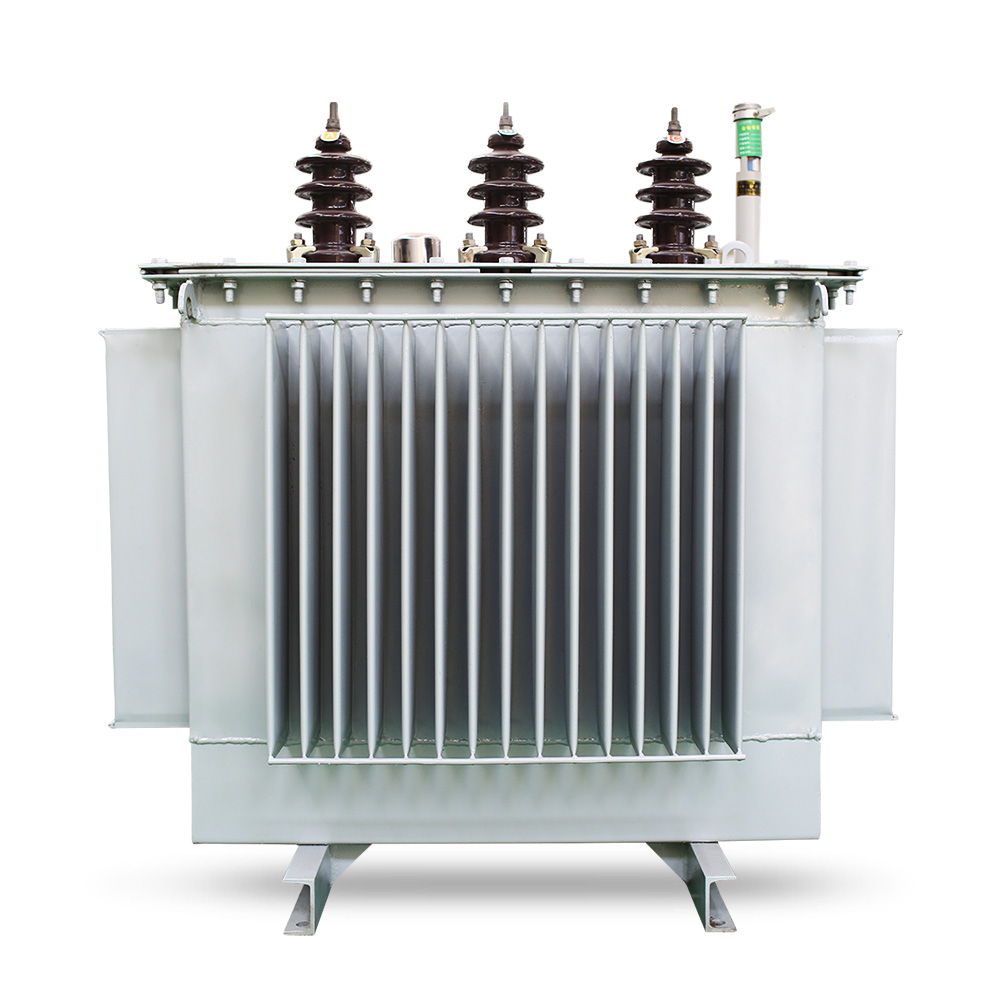

The power transformer oil tank is the outer casing of the transformer, containing the iron core and windings and filled with transformer oil, so that the iron core and windings are immersed in the oil. The transformer oil provides insulation and cooling.

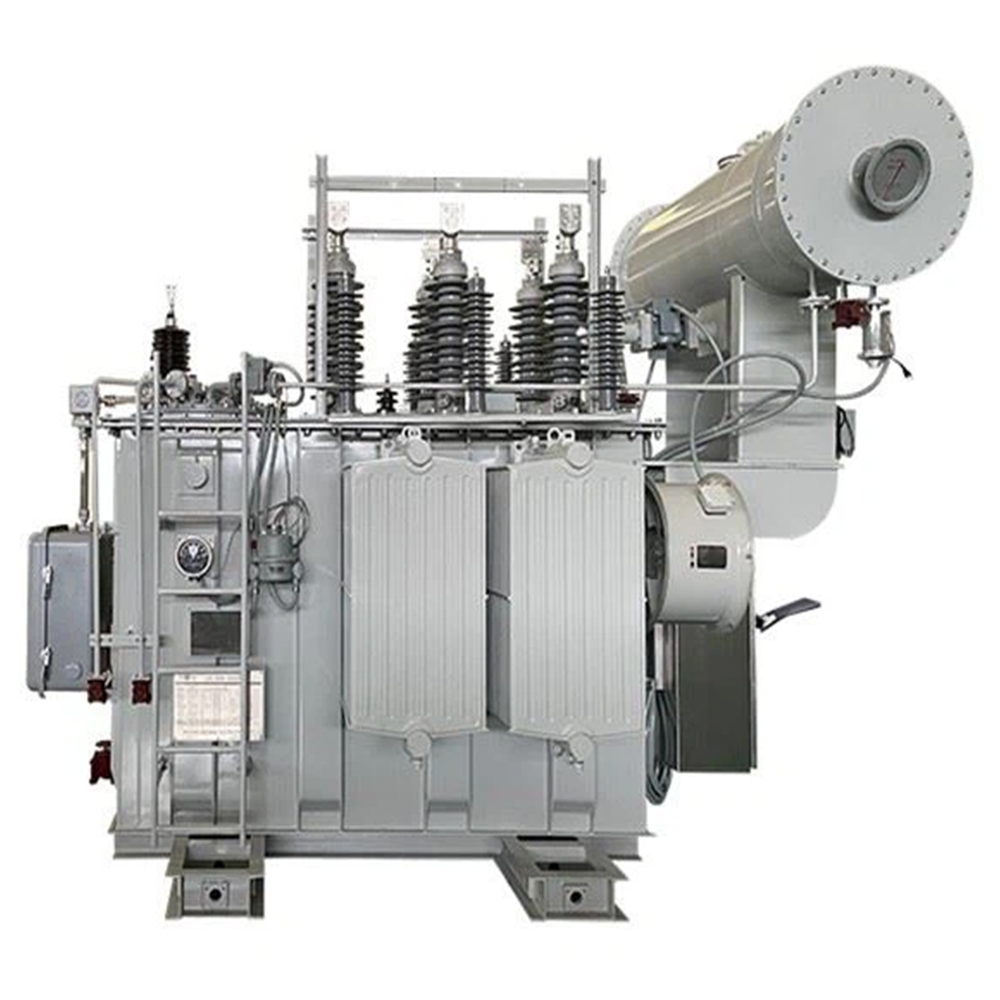

Large transformers generally have two oil tanks: one for the main body and one for the on-load tap changer. The on-load tap changer is housed in a separate tank because the tap changer generates electric arcs during operation, and frequent operation would degrade the insulation performance of the oil. Therefore, a separate tank is used to house the tap changer.

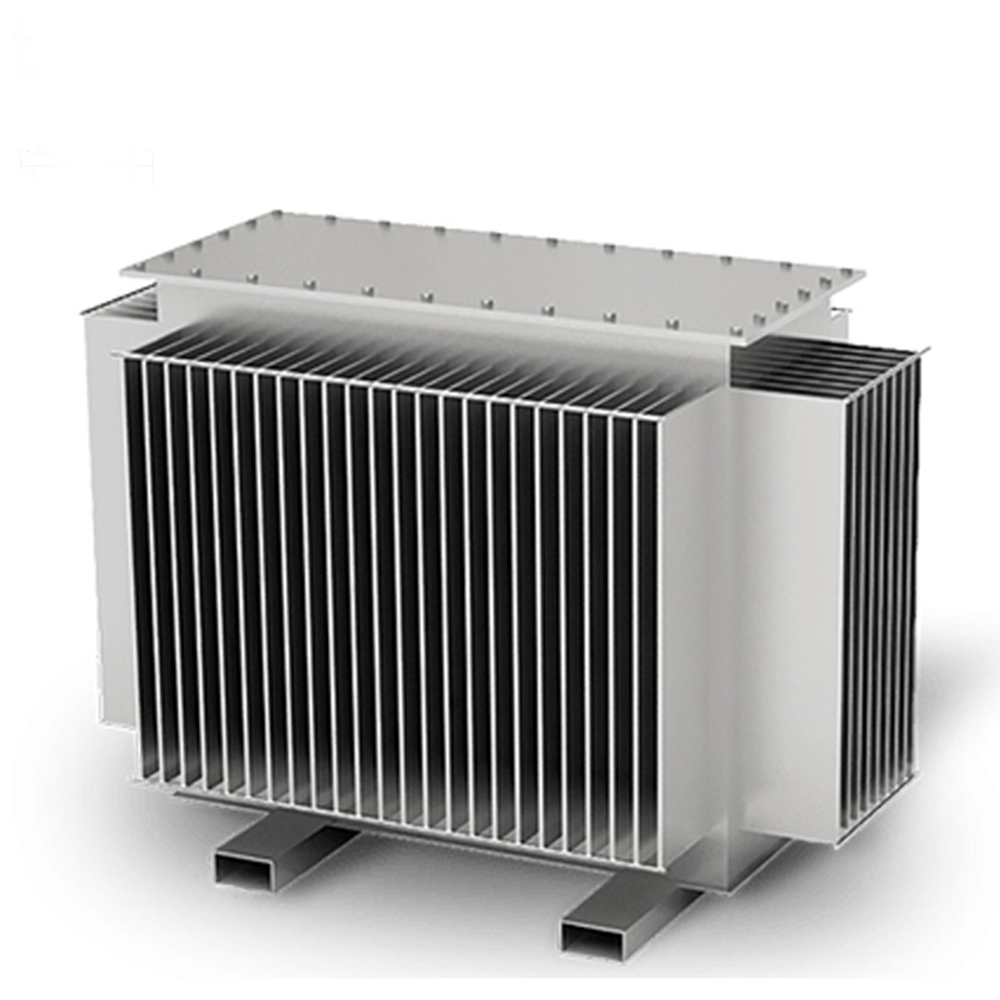

Transformer Oil Tank Structure

The corrugated oil tank of an oil-immersed transformer consists of an oil tank body and two long and two short corrugated plates installed on the outside of the tank body. The long and short corrugated plates are pressed and formed using a special corrugated forming line and welded together using gas shielded welding. The two short corrugated plates have right-angle edges on both sides, and the long corrugated plates are inserted into the inner side of the right-angle edges of the two short corrugated plates. The right-angle edges of the short corrugated plates are connected to the long corrugated plates on the outside, which facilitates welding between the long and short corrugated plates, improving welding efficiency and quality and reducing leakage rate. Transformers equipped with this type of oil tank have the advantages of small size, good heat dissipation, and attractive appearance.

There are basically two types of finned oil tanks: (Models: S11, SZ11, SFZ11, etc.)

Corrugated transformer oil tank (Models: S9, S11, ZS11, SHB11)

Applicable Transformer Range

10kV, 35kV voltage levels;

Capacity 10kVA~8000kVA;

Ordering Information for Transformer Oil Tanks

Custom manufacturing based on drawings.

Design and custom manufacturing based on capacity and voltage level.

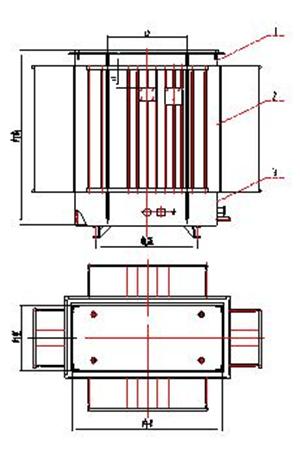

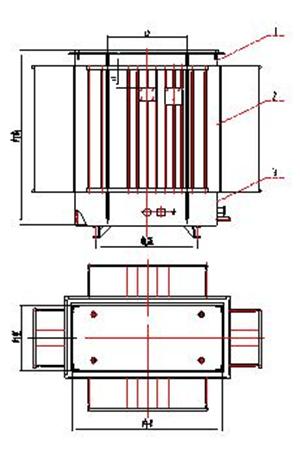

Transformer Oil Tank Structure Diagram

Transformer Oil Tank Structure Diagram

Tank Rim-1

Corrugated Wall-2

Tank Bottom-3

Power Transformer Oil Tanks Features

Power transformer oil tanks (corrugated oil tanks) are filled with oil, but the oil level in the transformer’s conservator should not be too full. The oil tank and the oil conservator are connected by a pipe. When the oil tank is low on oil, the oil from the oil conservator flows down the pipe to replenish the tank, keeping it full. Similarly, when the transformer load increases, the oil temperature rises, and the transformer oil expands, the excess oil flows back up the pipe into the oil conservator.

The cooling tubes inside the transformer oil tank (corrugated oil tank) contain cooling oil and are pipe-shaped. The vertical design of the transformer oil tank (corrugated oil tank) allows the cooling oil to circulate through convection (due to density changes caused by temperature variations), improving heat dissipation efficiency.

Transformer oil tank dimensions

| Rated capacity (kVA) |

Length |

Number of pieces |

Wavelength/Pitch |

Height |

Inner length × Inner width × Inner height |

Base dimensions |

Track gauge dimensions |

| 50 |

727 |

8 |

80 |

400 |

700×270×585 |

50×37×4.5Channel steel |

400×400 |

|

297 |

3 |

|

|

|

|

|

| 80 |

797 |

9 |

80 |

500 |

770×295×630 |

50×37×4.5Channel steel |

400×400 |

|

322 |

3 |

|

|

|

|

|

| 100 |

807 |

12 |

60 |

500 |

700×305×665 |

50×37×4.5Channel steel |

400×400 |

|

332 |

5 |

|

|

|

|

|

| 125 |

802 |

15 |

50 |

500 |

775×300×695 |

50×37×4.5Channel steel |

550×550 |

|

327 |

5 |

|

|

|

|

|

| 160 |

832 |

15 |

50 |

500 |

805×310×715 |

50×37×4.5Channel steel |

550×550 |

|

337 |

5 |

|

|

|

|

|

| 200 |

887 |

16 |

50 |

600 |

860×330×750 |

50×37×4.5Channel steel |

550×550 |

|

357 |

6 |

|

|

|

|

|

| 250 |

917 |

17 |

50 |

600 |

890×345×780 |

80×43×5Channel steel |

550×550 |

|

372 |

6 |

|

|

|

|

|

| 315 |

972 |

18 |

50 |

600 |

945×360×845 |

80×43×5Channel steel |

550×550 |

|

387 |

6 |

|

|

|

|

|

| 400 |

1017 |

19 |

50 |

600 |

990×375×885 |

80×43×5Channel steel |

550×550 |

|

402 |

7 |

|

|

|

|

|

| 500 |

1047 |

20 |

50 |

700 |

1020×390×925 |

80×43×5Channel steel |

660×660 |

|

417 |

7 |

|

|

|

|

|

| 630 |

1127 |

21 |

50 |

700 |

1100×420×970 |

80×43×5Channel steel |

820×820 |

|

447 |

8 |

|

|

|

|

|

| 800 |

1181 |

22 |

50 |

800 |

1150×440×1020 |

80×43×5Channel steel |

820×820 |

|

471 |

8 |

|

|

|

|

|

| 1000 |

1191 |

23 |

50 |

800 |

1160×450×1060 |

80×43×5Channel steel |

820×820 |

|

481 |

8 |

|

|

|

|

|

| 1250 |

1251 |

24 |

50 |

800 |

1220×465×1105 |

100×48×5.3Channel steel |

820×820 |

|

496 |

9 |

|

|

|

|

|

| 1600 |

1266 |

24 |

50 |

900 |

1235×470×1210 |

100×48×5.3Channel steel |

820×820 |

|

501 |

9 |

|