What Is A “Box-Type Substation” For Charging Piles?

05-03 2025 | By:

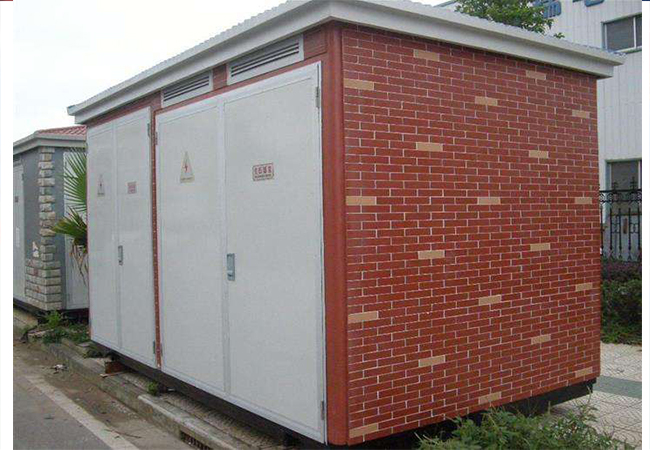

Box-type transformers are referred to as box transformers. Literally, the entire transformer equipment is installed in a box, just like building a house for these equipment in advance. This “house” is moisture-proof, rust-proof, moisture-proof, rat-proof, and heat-insulated, and is a very good house for substation equipment. Compared with traditional substations, they have the characteristics of small footprint and environmental protection. It is suitable for three-phase AC systems with a rated voltage of 10/0.4KV, as a line and distribution of electric energy. It is particularly suitable for urban network construction and transformation, and is a new type of substation that has emerged after civil substations. So what are the specific functions, characteristics, models, classifications and structures of box-type substations? Let’s talk about it in detail in this article.

The role of box-type substations

Box-type substations, also known as prefabricated substations or prefabricated substations. It is a kind of factory prefabricated indoor and outdoor compact distribution equipment that is arranged in a certain wiring scheme, which is a high-voltage switchgear, distribution transformer and low-voltage distribution device. It is an organic combination of transformer step-down and low-voltage distribution functions, and is installed in a moisture-proof, rust-proof, dust-proof, rat-proof, fire-proof, anti-theft, heat-insulated, fully enclosed and movable steel structure box. It replaces the original civil construction distribution room and distribution station, and becomes a new type of complete set of transformer and distribution equipment. It is suitable for the three-phase AC system with a rated voltage of 10/0.4KV, as a line and distribution of electric energy.

Features of box-type transformer substation

High-voltage/low-voltage prefabricated box-type substation (station) is also called box-type substation or combined substation (combined box-type substation), complete substation, and movable substation. Its structure is generally a box-type structure, with three parts: high-voltage switch room, transformer room and low-voltage distribution switch room. The rated voltage is 10, 35kV, and transformers of 1600kVA and below can be installed. Its characteristics are: small footprint; factory production, fast speed, good quality, fast construction speed, only the foundation part of on-site construction is beautiful in appearance, and can be coordinated with the environment of the residential area; strong adaptability, interchangeability, easy to standardize and serialize; small maintenance workload, saving investment.

Models of box-type substations

At present, there are many types of modular substations in China, including outdoor, indoor, fully enclosed and semi-enclosed, with corridor, without corridor, combined, fixed, installation, thousand-type transformer, oil-immersed transformer terminal power supply, ring network power supply, etc., which can meet the needs of different users.

The layout of the high voltage, transformer and low voltage three rooms is a mesh-shaped arrangement or a product-shaped separation scheme. The electrical high voltage room equipment components are imported, domestic or imported ring network cabinets, load switches plus current limiting fuses, and vacuum circuit breakers.

The low voltage room is composed of power, lighting, metering and reactive compensation cabinets. Ventilation and heat dissipation are equipped with fans, automatic temperature controllers, and anti-condensation controllers. The box shell is mostly made of ordinary or hot-dip galvanized steel plate or aluminum alloy plate, and the frame is welded with formed steel or connected with bolts.

EU substation

Classification of box-type substation

Box-type substations can be divided into European, American and integrated types. European box-type substations use the transformer as a separate component, integrating high-voltage cabinets, transformers and low-voltage cabinets into one or several boxes according to a certain wiring scheme to form a compact complete set of power distribution equipment. There are two ways to construct the box, namely the “目” shape layout and the “品” shape layout. The high and low voltage rooms in the “目” shape layout are wider, which is convenient for realizing the ring network or dual power supply wiring ring network power supply scheme.

(1) European box-type substation

The high-voltage room of the European box-type substation is generally composed of high-voltage load switches, high-voltage fuses and lightning arresters, which can be used for power outage operations and have overload and short-circuit protection. The low-voltage room is composed of low-voltage air switches, current transformers, ammeters, voltmeters, etc. Transformers are generally S9 or Qian type.

(2) American box-type substation

The American box-type combined transformer is divided into two parts, the front part is the wiring cabinet, which includes high and low voltage terminals, high voltage load switches, plug-in fuses, high voltage tap changer operating handles, oil level gauges, oil thermometers, etc.; the rear part is the oil tank and heat sink, and the transformer windings, cores, high voltage load switches, and plug-in fuses are all inside the oil tank. The box adopts a fully sealed structure. The integrated box transformer was recently developed by domestic manufacturers and is not widely used. It is a double-layer structure with high and low voltage chambers placed above the transformer chamber.

(3) Advantages and disadvantages of European and American box-type substations

Outdoor Box-type Substation

European, American and integrated box transformers have their own advantages and disadvantages. The European box transformer is larger in size, and the high and low voltage switches and transformers are all located in a large shell. The heat dissipation conditions are poor and a mechanical exhaust device is required. The American box transformer has relatively good heat dissipation conditions because the transformer cooling fins directly dissipate heat to the outside, but its shape is worse than that of the European style and its appearance is difficult to match with green environments such as residential areas. The integrated box transformer occupies less space, and its advantages and disadvantages are similar to those of the American box transformer. In addition, the American and integrated box transformers can only be manufactured in China with a capacity of less than 630kVA, while the European box transformer can reach 1250kVA.

The structure of the box transformer substation is related to the space required for various wiring equipment. The ring network and terminal power supply line schemes are designed in two categories: closed and semi-closed. The high and low equipment rooms are divided into structures with operating corridors and without operating corridors, which can meet the needs of any combination of six load switches, vacuum switches, etc. The high-voltage room, transformer room, and low-voltage room are arranged in a straight line. According to the requirements of transportation, they are designed in two types: integral type and sub-unit disassembly type.

13.8kV Outdoor Pad-Mounted Transformer

Structure of box transformer substation

The box body of the box transformer substation adopts two types: steel plate sandwich (can be filled with asbestos) and composite board, and the top cover is sprayed with colored sand latex. The box body has rainproof performance. In order to monitor, repair, and replace equipment, a universal door is designed, which can be opened with double leaves or single leaves. The transformer room is equipped with a structure with doors on both sides. The transformer compartment has tracks for moving the transformer (nameplates and danger signs are set at obvious places on the shell). The outer shell has ventilation holes and heat insulation measures. If necessary, heat dissipation measures can be adopted to prevent the internal temperature from being too high.

The air temperature in the small room of high and low voltage switchgear should not cause the temperature of each component to exceed the requirements of the corresponding standards. At the same time, measures are taken to ensure that no condensation occurs inside when the temperature changes sharply. When there is a vent, there should be a dust filter.

Model of box-type substation

The high-voltage side of the box-type substation meets the requirements of “five protections”. In the case of no power, there is a reliable grounding device after the door is opened. Only when there is no voltage signal indication, the live part can be repaired. After the high and low voltage side doors are opened, there is a lighting device to ensure the safety of operation and maintenance.

The box-type substation has four ways of inlet and outlet: overhead line inlet and outlet, cable inlet and outlet, overhead line inlet and cable outlet, and cable inlet and overhead line outlet.

The 10kV distribution device of the usually uses a load switch plus a fuse and a ring network power supply device, which is connected from the adjacent overhead line to the high-voltage end of the transformer. The incoming line can be a cable line or an overhead insulated line. When used as a public box-type substation, the low-voltage outgoing line of the box-type substation depends on the capacity of the transformer. Generally, it does not exceed 4 circuits, and at most does not exceed 6 circuits. It can also be a total outgoing line, and then branch power supply to the adjacent distribution room. When used as an independent user box-type substation, a single circuit power supply can be used.

You may also find these interesting: