Copyright © 2022 hnztelec. All rights reserved.

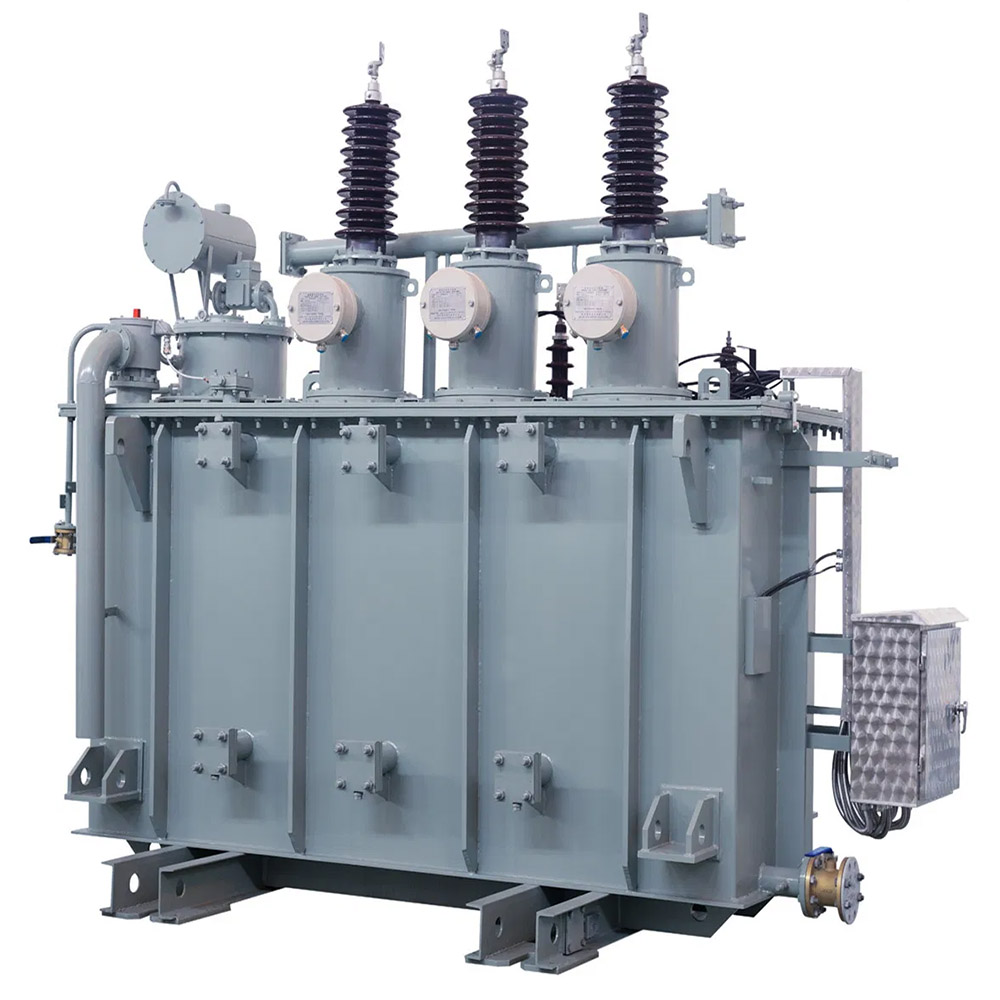

66kV Oil-Immersed Power Transformer

| Rated voltage | 66/110KV |

|---|---|

| Rated capacity | 6300KVA-63MVA |

| Application scenarios | Substations, photovoltaic power plants, steel mills, airports, ports, etc. |

| Certifications & Standards | EC、GB、ANSI/IEEE、NEMA |